Your comments

Hi, you need to close the info window - then it should continue.

Hi,

if you question is a bout the "disable" of the PLCInput and PLCOutput script this only disables the FixedUpdate functions because they are not needed. The Signals are more or less passive Gameobjects only holding the information of the signal values and the connection.

Hope this helps.

Best regards

Thomas

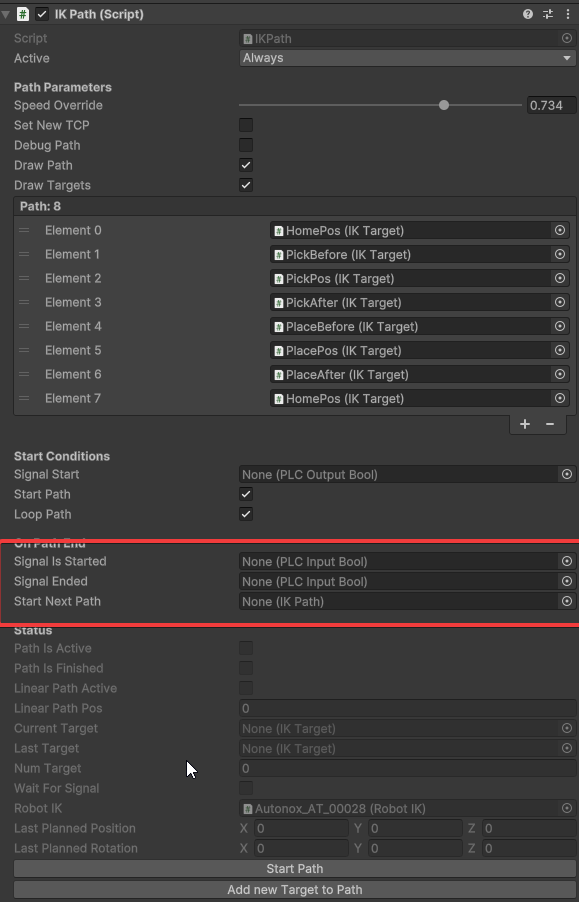

Hi Niko, what about using the Signals? You need to create a Signal Gameobject, assign it to SignalEnded and check it like MySignalEnded.Value = true. Maybe it would be also a good idea for the next release to add here event functions so that you could subscribe with your custom methods.

Hi,

I've checked your setup in our current release and I'm not able to get this error.

Which realvirtual release do you use?

The error suggests that the MU lost connection to the transport surface. Are there other colliders nearby?

How is the structure of your MU? Are MU and Rigidbody-component on the same gameObject?

Regards

Christin

Customer support service by UserEcho

Hi, we just checked and can't reproduce. Can you send us a full Unity project with everything in where we can test this. Please upload your project to https://realvirtual.io/send