Ihre Kommentare

Hi Thomas,

yes you're right. I wasn't clear that I had to select a scene in the build settings. This seems to be different in Unity 2022.

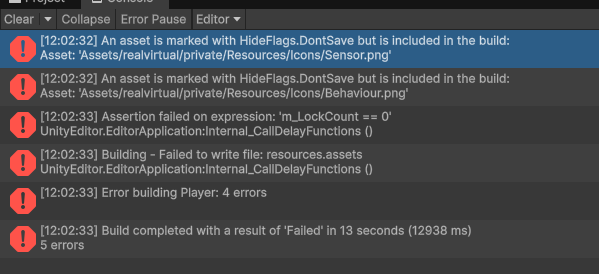

Also I had errors in the console:

I remember those similar errors when doing a build in Unity 2022.

What I had to do is to change the texture type of both 'png' to something else and then back to default. Is this a known problem?

After fixing that and selecting the demo scene the build is working properly.

Thanks for your fast reply!

Thank you for your response.

There seems to be a difference if the scene is created via File > New Scene > RV Template or if created via Menu realvirtual > Create new realvirtual Scene.

If created directly via realvirtual menu the lightning works just fine.

Can you please take a look on my last question please?

Thank you for your reply.

Do you know if it is possible to change the decimals also?

I can't change the value by the slider to e.g. 245,1.

I did a work-around to solve this issue by using the property "Value" and public function "Init" of HMI_Slider.

Is it possible to use the Hmi_Slider with changing decimals? Currently it's only showing decimals but I can't change it with the slider.

Could you also add a "HMI_ValueBox" or something where it is possible to enter values by keyboard?

Best regards

Andreas

I made some pre-work and implemented this public function in IKPath.cs:

**********

//! Added by AF for canceling active paths

public void CancelPath()

{

if (CurrentTarget != null)

CurrentTarget.OnLeaveTarget();

LastTarget = null;

CurrentTarget = null;

NumTarget = 0;

PathIsActive = false;

WaitForSignal = false;

// Reset all Values for all motion types

drivesatposition.Clear();

linearpathspeed = 0;

linearpathacceleration = 0;

linearacceleration = false;

lineardeceleration = false;

LinearPathActive = false;

LinearPathPos = 0;

}

**********

I realized a problem though.

If the current path gets canceled and the next path starts with a linear movement to the target, the robot makes a "jump".

This is caused in RobotIK.cs

After picking the box the robot path gets canceled and another path starts with linear movement.

It might help you with your development work.

Do you need my project for this?

I had similar problems when I tried the RobotIK for the first time.

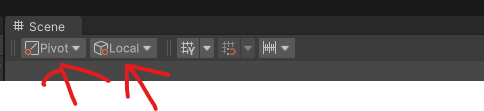

You have to do I exactly like in the tutorial video and set up the scene settings to the following:

This was the game changer for me haha

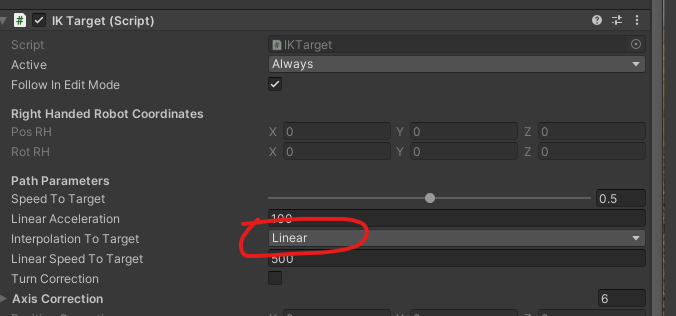

Okay, I found it.

Just need to set interpolation to target on linear.

Customer support service by UserEcho

Hi,

I tried it but when changing to game mode the camera swings to another position.

I deactivated he camera positions scripts completely.

Why is the camera still moving?