Your comments

Did it worked with just different parameters or did it only worked with the Update which I have send you?

Oh sorry, totally missed to check this. Will check it on Monday and let you know.

I am sorry, I can't tell you this. We are using

https://libplctag.github.io as an underlying library. Maybe you can find some more info about this on their pages. Best regards Thomas

Did you checked the player log if there are some error messages?

Hi,

try deleting the inverse kinematics (folder IK) in the Professional folder. This may also have problems with WebGL. Please let us know if this solves the problem.

Regards Christin

Hi,

this error may possibly be due to a space in the path. Please test it with a path without spaces or special characters.

Regards Christin

Hi, with WebGL you can only use Websocket based interfaces. This is a limitation by the Web standard and browsers and there is no way around that. This is why currently only a TwinCAT WebGL based interface is running with WebGL. All other PLC interfaces use different communication standards and don't work on WebGL.

Hi, you would need to delete some folders because mainly some interfaces are not working with IL2CPP and WebGL.

Please check the table here for knowing in detail what to delete:

https://doc.realvirtual.io/advanced-topics/supported-platforms

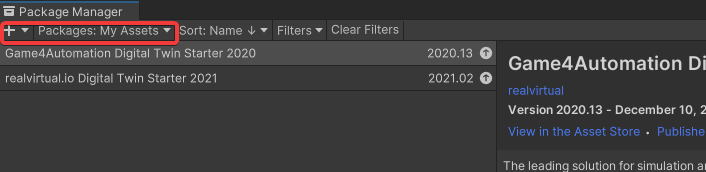

You should find it under "My Assets" - did you checked to find it there?

Customer support service by UserEcho

Hi, the solver will not get any values greater or lower than -180 or +180 because with this solutions all possible positions can be described.