Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Simulation window paused when window not active

Simulation window paused when window not active

I have a question about the Unity environment. It pauses when I have another program active. How can I solve this issue?

Override values (Unity to PLC) does not work as expected

Override values (Unity to PLC) does not work as expected

Greetings.

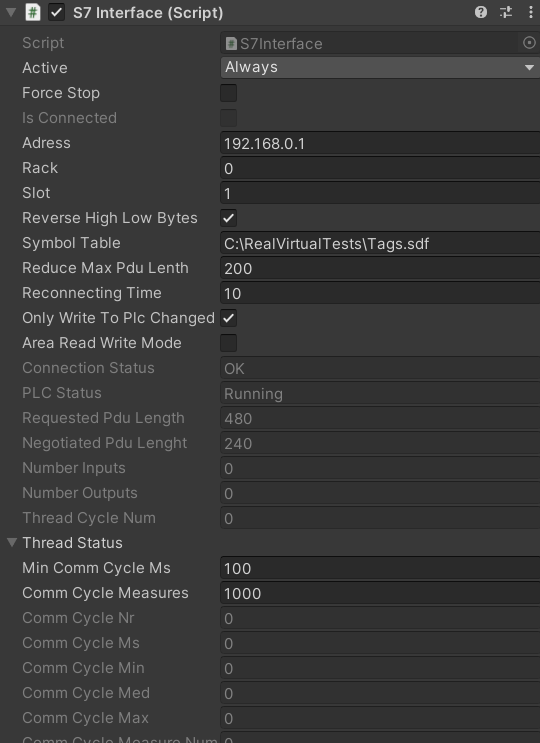

I am using S7 TCP/IP connection on a Unity project and I am physically connected to an S7-1200.

I am using various PLC Inputs and Outputs (created automatically from the .sdf file).

The PLC outputs are being read correctly on Unity, but when I force (overrite) a BOOL input value, the PLC detects the change but does not hold the new value. For example, I can see on the TIA Portal monitor window that the value is FALSE. I press write to True on Unity but the monitor on TIA Portal still shows False, although it did acknowledge the pulse (mabye it was a very short pulse)? Is this the way writing to PLC inputs works? By pulses? Because I would like to change a boolean (or any other type) value and hold that state for long periods of time.

These are my settings for the S7 Interface

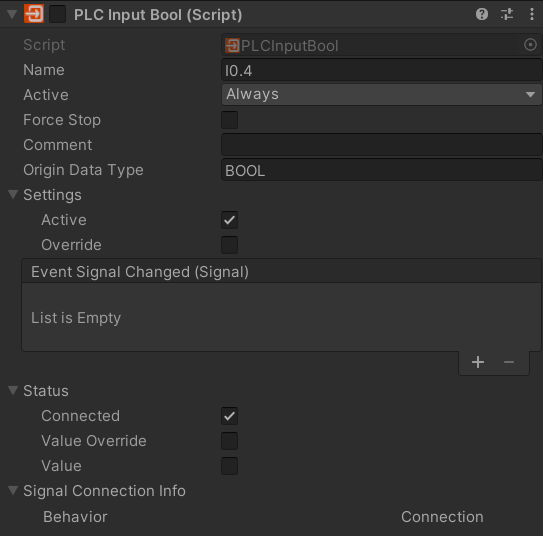

And this is an example of a PLC Input component (Is it normal that the component is deactivated during runtime??):

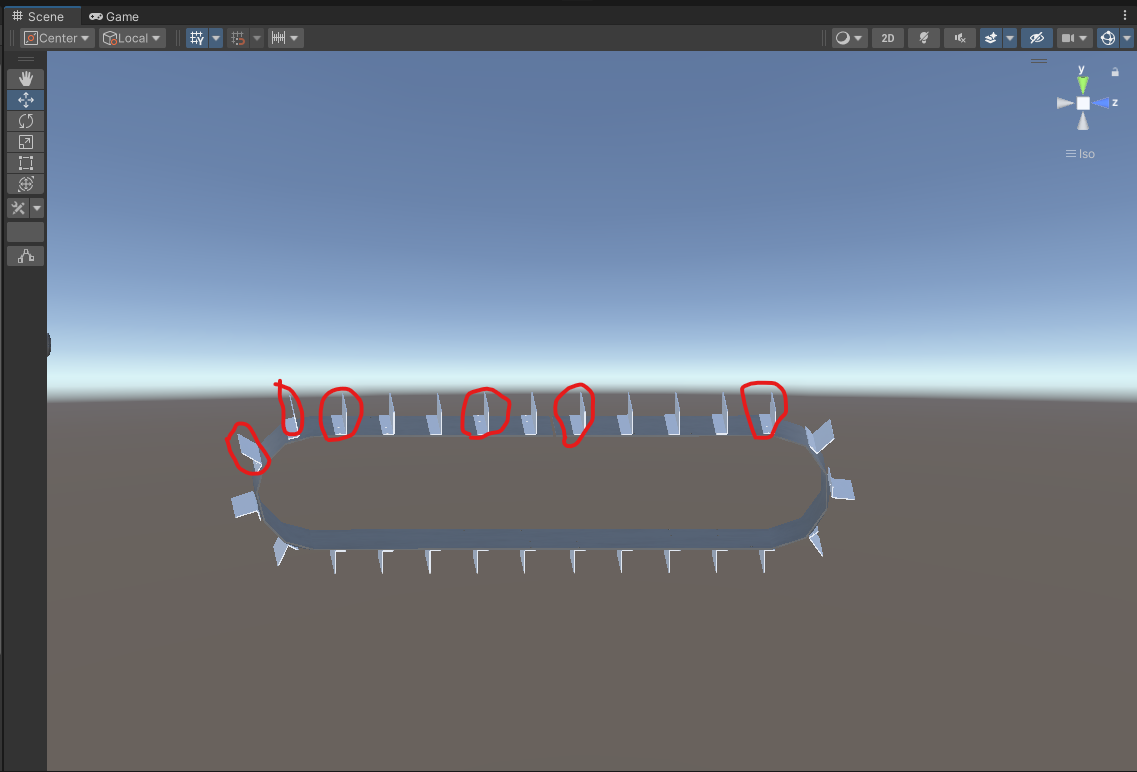

This is the correspondent GameObject during runtime:

Thanks for your time!

Hi Andreas,

here are my answers:

- This behavior is by design from Siemens. It's not possible to change this. If a hardware value is at a certain level, you can't overwrite it with software.

- This is not a bug; it's a common characteristic of all software solutions utilizing real Siemens PLC hardware. To avoid values being overwritten, you can modify your hardware configuration or use a simulated PLC.

To the best of my knowledge, you don't need to change the program itself. However, you do need to adjust the hardware configuration to ensure the symbol you are using does not conflict with a real hardware input.

Solutions that Work Without Changing Hardware Configuration for Siemens Controllers:

- Use PLCSimAdvanced

- Use Simit in Combination with a Simulation Unit

[Reccomanded] RealVirtaul 2022 HMI Source Omission

[Reccomanded] RealVirtaul 2022 HMI Source Omission

Hi, I am using realvirtual very well.

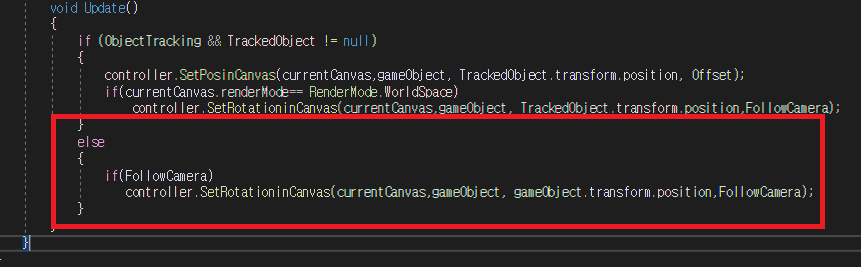

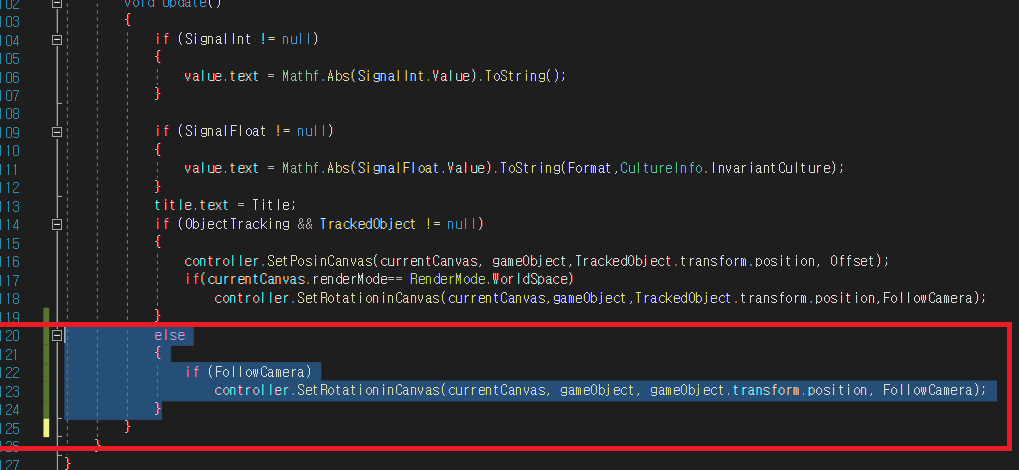

I find that there some Differences in HMI_Value.cs , HMI_Text.cs

One Function of 'Follow Camera' in HMI_Text.cs works very well.

because of 'else' in controller function

But The other Function of 'Follow Camera' in HMI_Value.cs omit the function of Tracking(else sources).

So, I reccomand you put into same function in HMI_Value.cs like below.

thks.

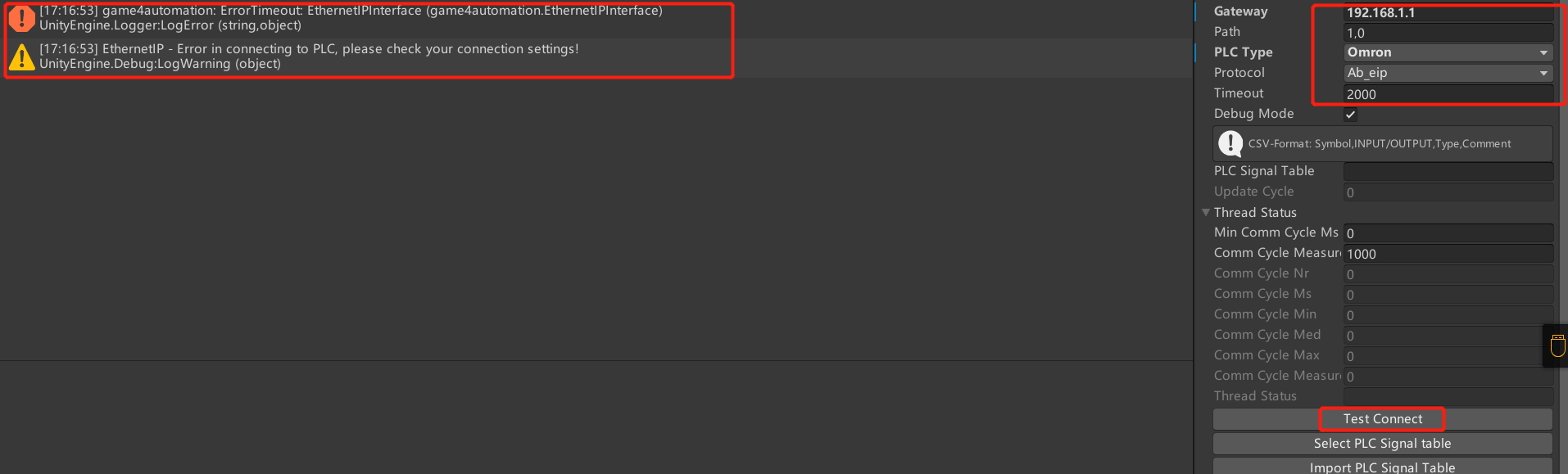

Inability to connect Omron plc via enternetip

Inability to connect Omron plc via enternetip

Dear

When connecting Omron PLC NX1P2 via enternetip, set the above parameters, then click the TEST CONNECT button, the connection fails, the computer can ping through 192.168.1.1, about the parameter path setting, it is not clear how to set, have tried in many ways, I can't even make a connection.

Thank you

Customer support service by UserEcho