Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Circular conveyor belt

Circular conveyor belt

Hi

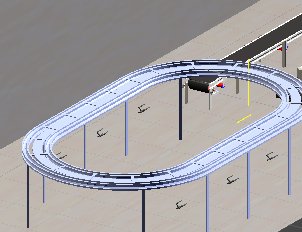

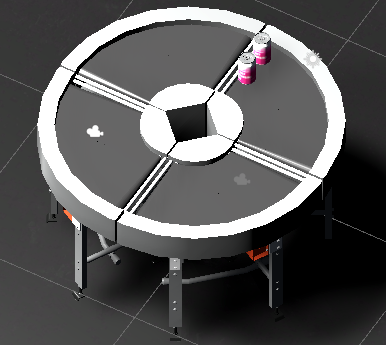

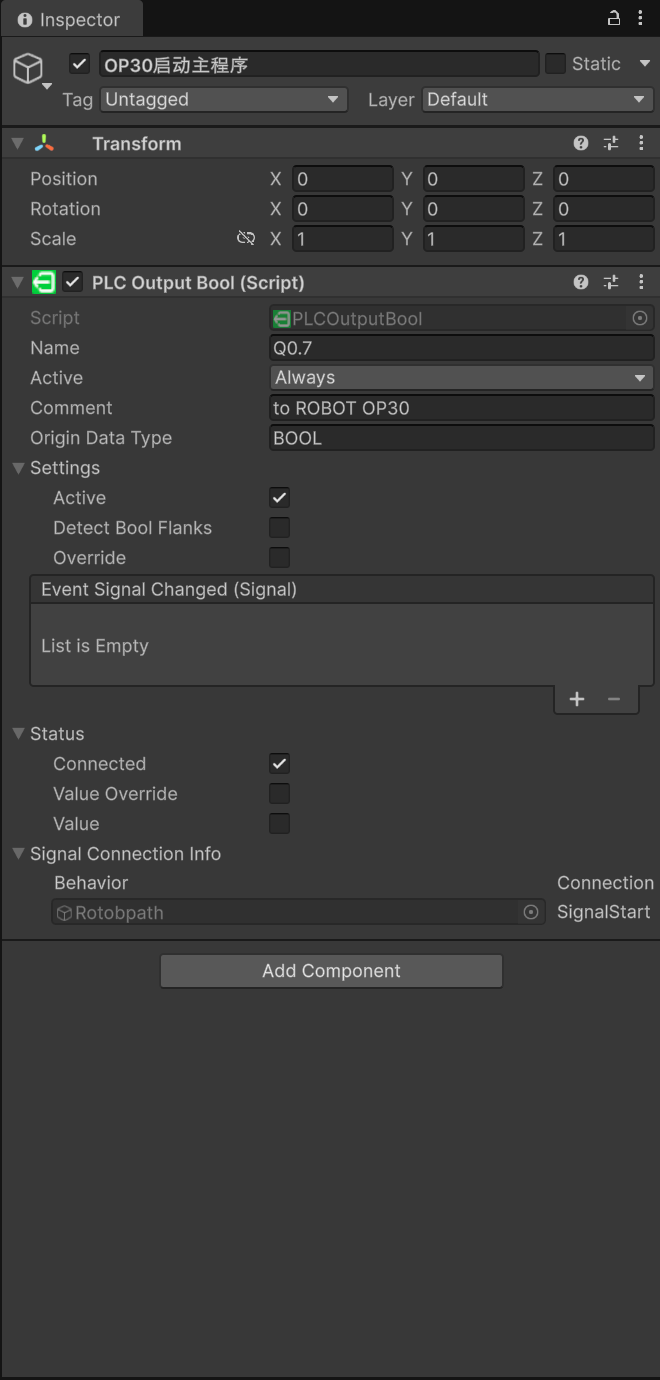

I wanted to achieve a circular conveyordemo effect (Fig1), a reference to radialConveyordemo (Fig2), but the MU transported in a circular conveyordemo is skewed in position, and I froze the XYZ rotation of the MU

Fig 1

Fig 2

[Help Needed] FANUC RobotInterface

[Help Needed] FANUC RobotInterface

Hi everyone,

I'm working with the FanucInterface component in realvirtual.io to connect Unity to RoboGuide.

I'm able to connect Unity and Roboguide through SNPX

I'm able to read UO and DO signals from the robot in Unity but I'm not able to write DI or UI signals.

Setup:

- RoboGuide: HandlingPro Classic Version 10 (Rev.C_SR4)

- Unity: Unity 6.2 with realvirtual.io V6.0.7.8152

[Help Needed] OPC UA Signal Direction Imported Incorrectly (Inputs recognized as Outputs and vice versa)

[Help Needed] OPC UA Signal Direction Imported Incorrectly (Inputs recognized as Outputs and vice versa)

Hi everyone,

I'm working with the OPCUAInterface component in realvirtual.io to connect Unity to a Siemens S7-1500 PLC via OPC UA, and I'm running into a frustrating issue with signal direction mapping.

Setup:

-

PLC: Siemens S7-1500

-

Unity side: Using

OPCUAInterfacefrom realvirtual.io -

In the PLC (TIA Portal), I've configured:

-

.inputsvariables as Read-Only (HMI accessible: Read only) -

.outputsvariables as Read/Write

-

-

In Unity:

-

I've tried enabling/disabling

Automatically Input On Write Signals -

I've set

Regex Write Nodes = (?i)\.outputsto match output variables

-

However, no matter what combination I try, the imported signal directions are reversed:

-

.outputsare imported as Input ❌ (they should be Output) -

.inputsare imported as Output ❌ (they should be Input)

What I Expect:

Based on my understanding of realvirtual.io's signal model:

-

Input= Unity reads from the PLC (e.g., sensors, status) -

Output= Unity writes to the PLC (e.g., buttons, control commands)

I expect .inputs to be imported as Input, and .outputs as Output.

Temporary Workaround:

I'm currently using a custom Unity script that runs after import and forcibly sets the signal direction based on the variable name (.inputs → Input, .outputs → Output).

This works, but feels like a hack and not a long-term or scalable solution.

What I'm Asking:

-

Is this a known limitation of Siemens OPC UA Server? (Does it misreport variable access rights?)

-

Is there a way to fully customize signal direction logic during import in

OPCUAInterface? -

What’s the recommended best practice for Siemens OPC UA + Unity signal mapping?

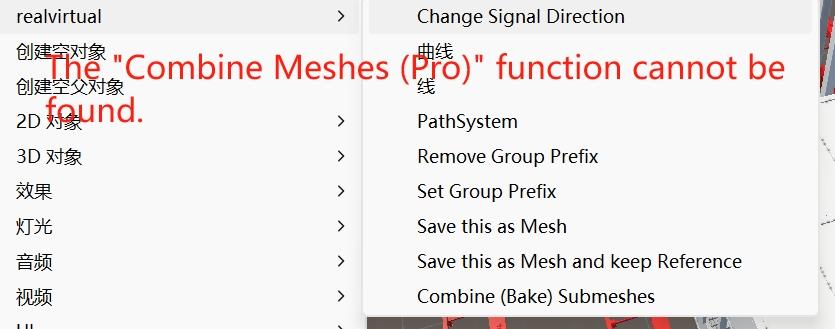

s7接口通讯问题

s7接口通讯问题

如你所见,我在用s7接口时出现了一点问题,我在S7-PLCSIM Advanced运行我的PLC时修改这一个值可以映射进unity,但是在unity中我尝试切换value却无法保持值,他就像切换了一下,但是马上被改回去了,我的值默认是false,点击切换后会短暂的显示true,但是还是会变回false,这是为什么,我在博途监控表里修改值是可以映射在unity中的,值也能正常切换,允许来自远程对象的 PUTIGET 通信访间也是勾选的,包括完全访问权限和仿真支持块编译也是勾选了,博途设置也没有问题,就是unity无法切换博途v20的值,我使用的版本是realvirtual.io6.2.1,博途版本是v20

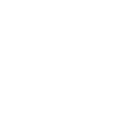

The "Combine Meshes (Pro)" function cannot be found.

The "Combine Meshes (Pro)" function cannot be found.

Why can't I find the "Combine Meshes (Pro)" function in the version I'm using? I have purchased the PRO version, so is this function only available in Professional 6?

One more question: Does realvirtual.io Digital Twin Professional 6 require a separate purchase? I noticed that 2022Pro has been discontinued.

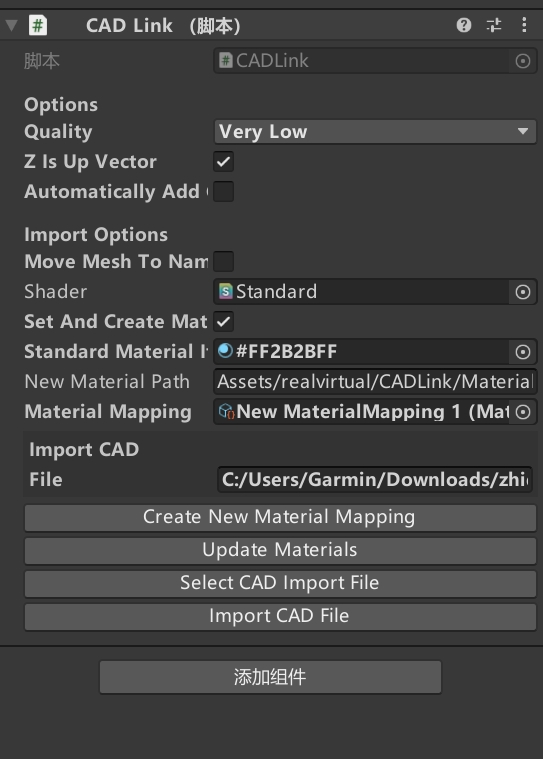

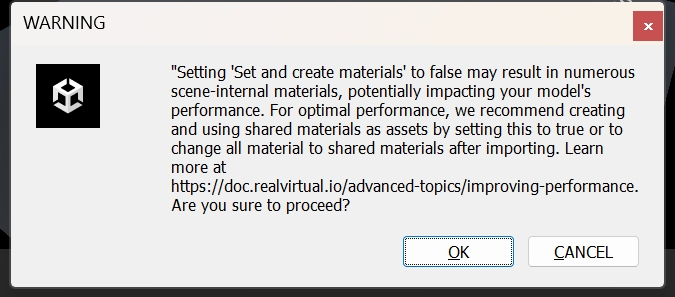

Regarding the issue of importing step from CADLINK

Regarding the issue of importing step from CADLINK

When importing step using CADLINK, "Set and create materials" has been clearly checked. However, after clicking "Import CAD File", this prompt still pops up. If the import continues, the program will crash.

Transport Surface - Issue with "Change Constraints on Enter / Exit"

Transport Surface - Issue with "Change Constraints on Enter / Exit"

I am having difficulty with changing constraints on enter/exit of a transport surface. I get the following errors in runtime.

NullReferenceException: Object reference not set to an instance of an object

realvirtual.TransportsurfaceCollider.OnCollisionEnter (UnityEngine.Collision other) (at Assets/realvirtual/TransportsurfaceCollider.cs:29)

UnityEngine.Physics:OnSceneContact(PhysicsScene, IntPtr, Int32)

NullReferenceException: Object reference not set to an instance of an object

realvirtual.TransportsurfaceCollider.OnCollisionExit (UnityEngine.Collision other) (at Assets/realvirtual/TransportsurfaceCollider.cs:41)

UnityEngine.Physics:OnSceneContact(PhysicsScene, IntPtr, Int32)

Now for the strange part, the transport surface IS correctly setting the constraint on enter (Freeze position x in my case), but this constraint does not get removed on exit. I do have "Change constraints on exit" set to true and "none" set for the constraints exit. In the "Loaded Part" list in the transport surface, there are no objects listed in runtime even though there are game objects on the transport surface.

Has anyone else ran into this issue before? Seems weird that I am getting that error on enter, but the constraint is still getting set correctly.

Questions about Modbus TCP connection to Siemens 200smart

Questions about Modbus TCP connection to Siemens 200smart

May I ask if your company has launched the modbus client access function? I need to enter an IP and PORT to access Siemens 200smart PLC.

IK Limits

IK Limits

I'm working on some digital twin of a 6 axis arm robot and would like to use the IK.

I actually have something that's currently working fine, but we've found out that some of the joints are reverse and that one of them needs an offset. However - once I fix all that the IK breaks.

I saw in the documentation that there are some strict limitations.

I just wanted to understand where am I still free to play around, and if it's possible to fix the IK somehow:

1. Can I reverse the joint's direction (the bottom two are fine but the rest need reversing)?

2. Can I add an offset so that when the 3rd joint is at 0 angle the robot will be at 90 degrees?

3. If not - is there some recommended method to convert the values so that they would fit the real values?

About the problem of reconnecting the s7plc to the caton

About the problem of reconnecting the s7plc to the caton

Hello, I have a question. If there are a lot of devices with a lot of IP, the PLC that is not turned on will be reconnected over time, and reconnecting the PLC over time will cause the program to stall, which will greatly affect the use. May I ask how to solve the problem of reconnecting over and over?

Hi, there would be changes in the code needed. Currently we don't assume that devices are off and on during simulation. The source code is open you would need to change the way how reconnection is done - maybe by using the new Awaitable System in Unity6

Customer support service by UserEcho