Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

[Not Solved] Compile Error after realvirtual AI Builder Package Installation with Unity 6 LTS Version

[Not Solved] Compile Error after realvirtual AI Builder Package Installation with Unity 6 LTS Version

Dear,

Sorry But,

The problem is not solved.

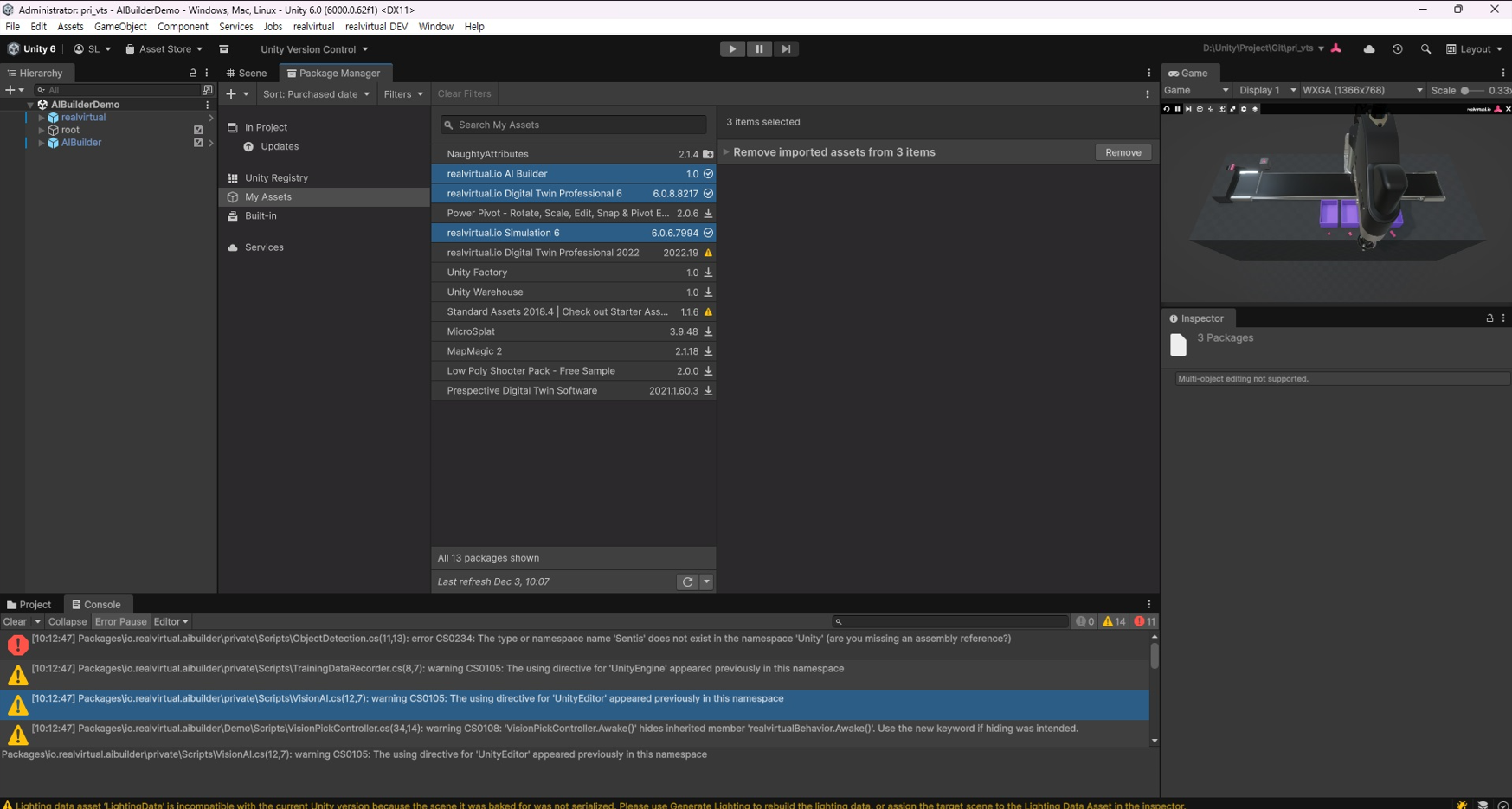

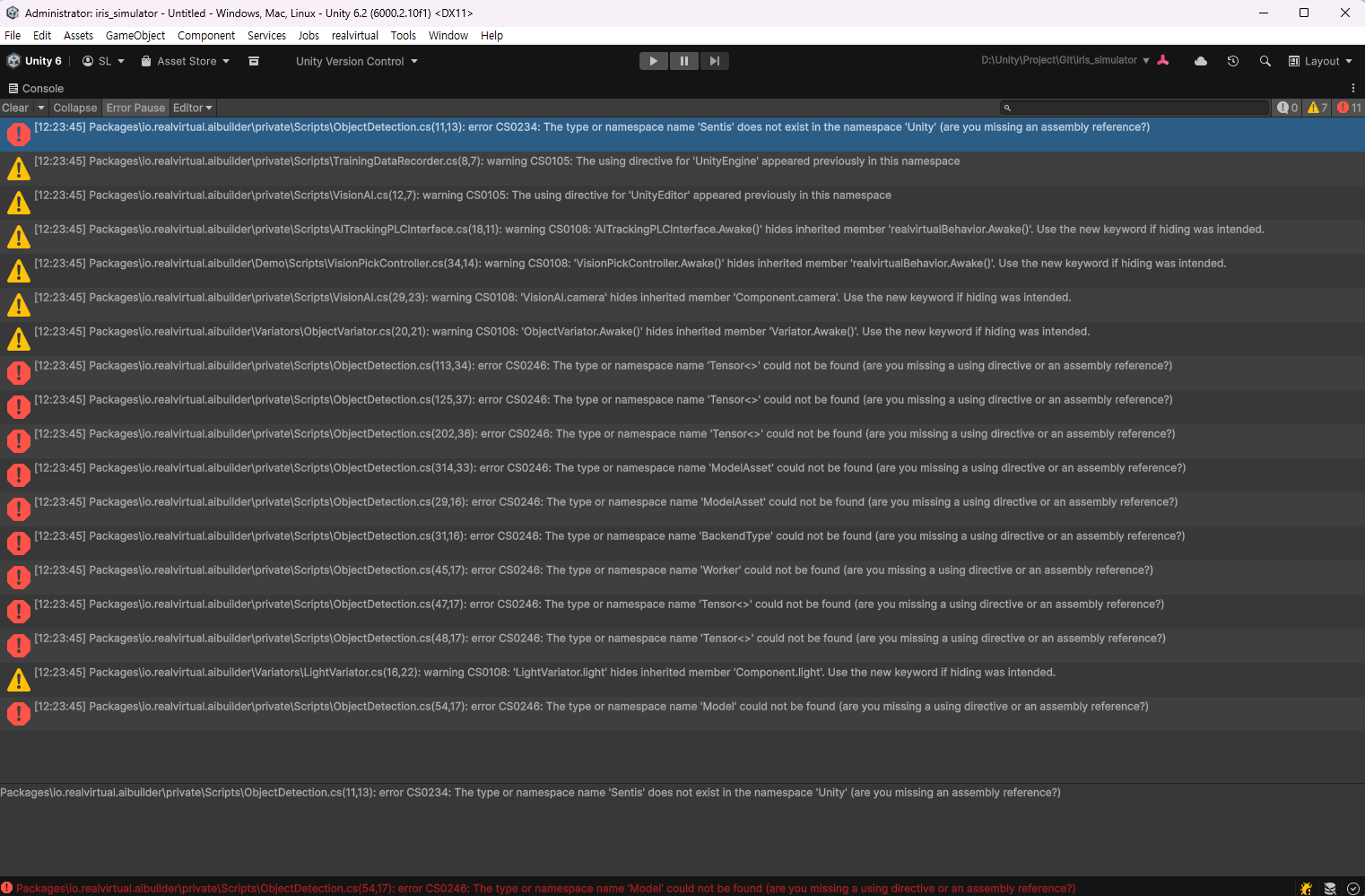

I'm having trouble again with a compile error after installing RealVirtual AI Builder with Unity 6 LTS version.

1) Unity 6 LTS Version (6000.0.62f1)

2) Install RealVirtual IO Digital Twin Professional (6.0.8) & Simulation 6 (6.0.6) → OK

3) Install RealVirtual IO AI Builder 1.0

→ Compile error occurs (see image below)

I would like to request guidance on how to resolve this issue so I can use RealVirtual AI Builder.

Source a MU without rigid body component?

Source a MU without rigid body component?

I would like to simulate pick and place processes of parts by using kinematics without physics. I am struggling with my understanding of the MU, Source, Grip/Fix concepts.

What do I have to do to make a sourced MU part a subcomponent without physics?

Compile Error after realvirtual AI Builder Package Installation with Sentis (InferenceEngine)

Compile Error after realvirtual AI Builder Package Installation with Sentis (InferenceEngine)

Dear,

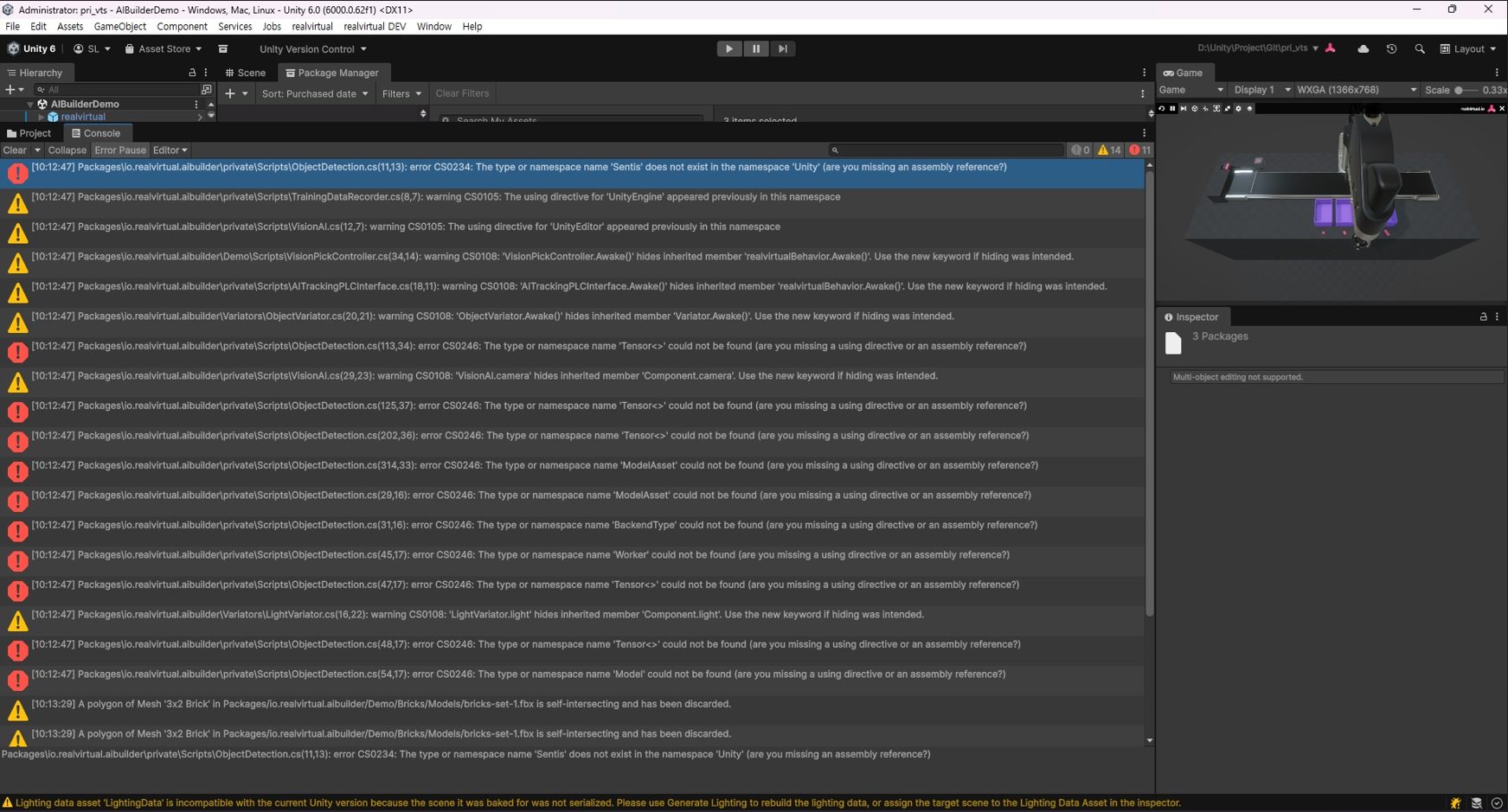

I'm having trouble with a compile error after installing RealVirtual AI Builder.

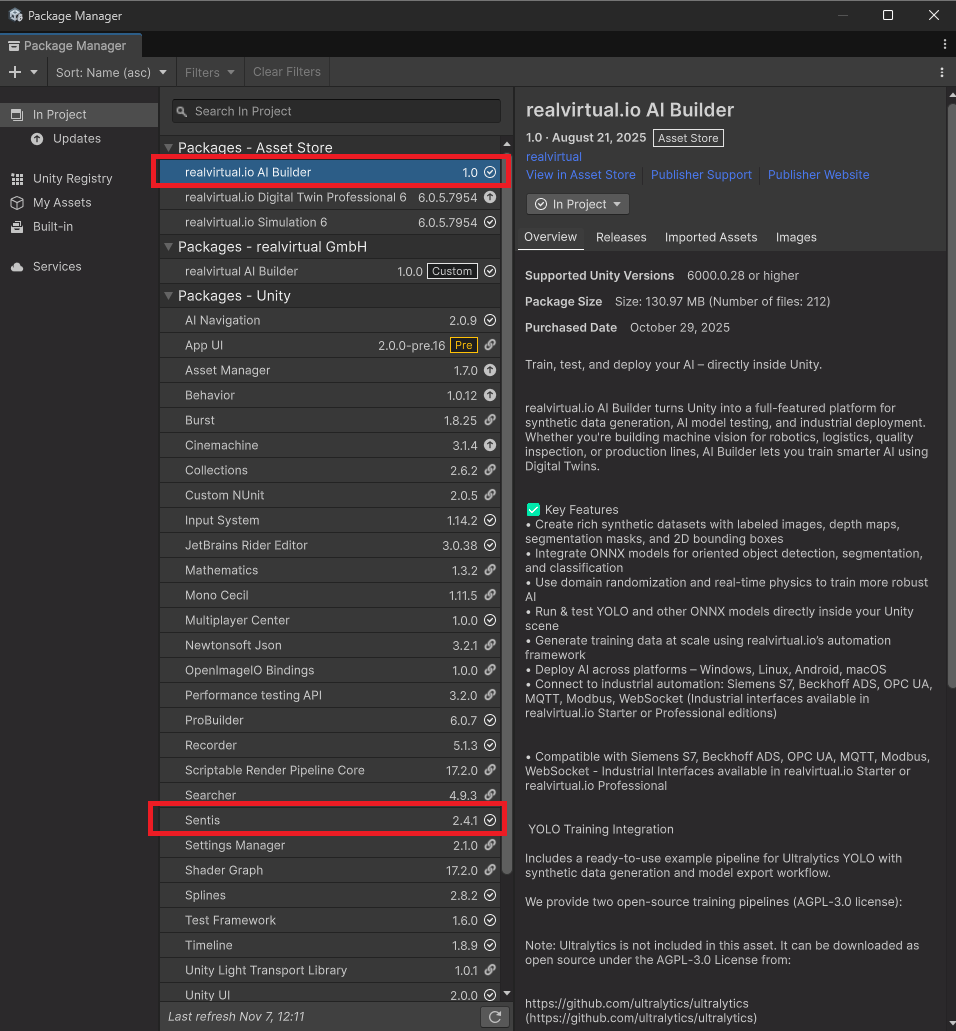

1) Install Sentis (InferenceEngine) 2.4.1

2) Install RealVirtual AI Builder 1.0

→ Compile error occurs (see image below)

To resolve this issue, I tried changing Unity.Sentis to Unity.InferenceEngine in the ObjectDetection.cs script where the error occurs, but this did not resolve the issue.

I would like to request guidance on how to resolve this issue so I can use RealVirtual AI Builder.

※ Package Installation Status: RealVirtual AI Builder & Sentis

※ Compile Error Status

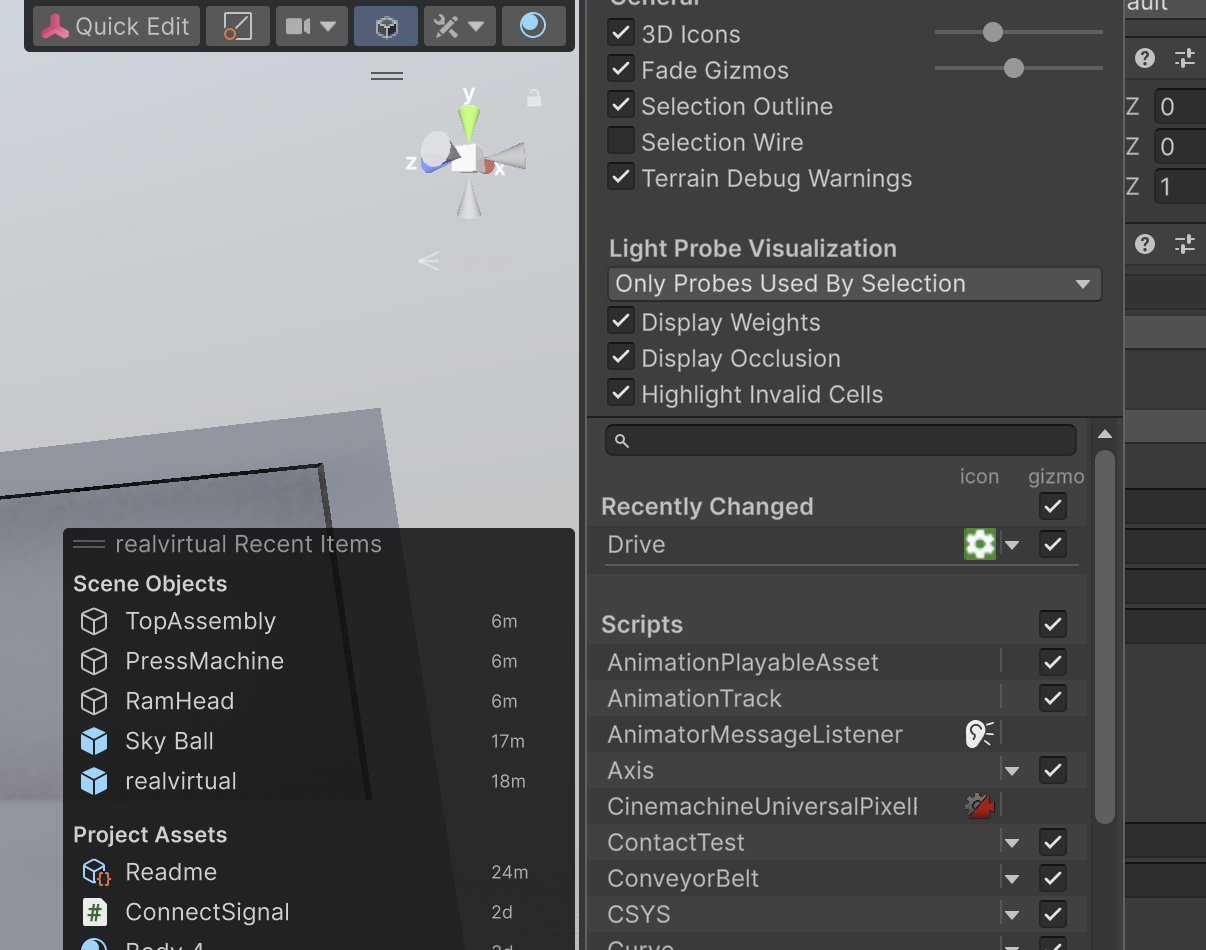

How can I use Modern Drive Gizmos and Drive handles in 6.0.7?

How can I use Modern Drive Gizmos and Drive handles in 6.0.7?

I'm starting out with RealVirtual, and I've ran into a problem right away regarding the UI.

In this doc, it says that a Modern Drive Gizmo should be shown When I select a drive, but I don't see any kind of handles other than native unity handles.

I checked the Drive in the settings panel and also added an icon, but I'm not seeing any kind of icons or gizmos in the main 3D view nor in the hierarchy view. This is a new clean project using Unity 6 LTS and RealVirtual 6.0.7. The only thing I've added is our 3d model that is not modified since import.

https://doc.realvirtual.io/components-and-scripts/motion/drive#modern-drive-gizmos-updated-in-6.0.3

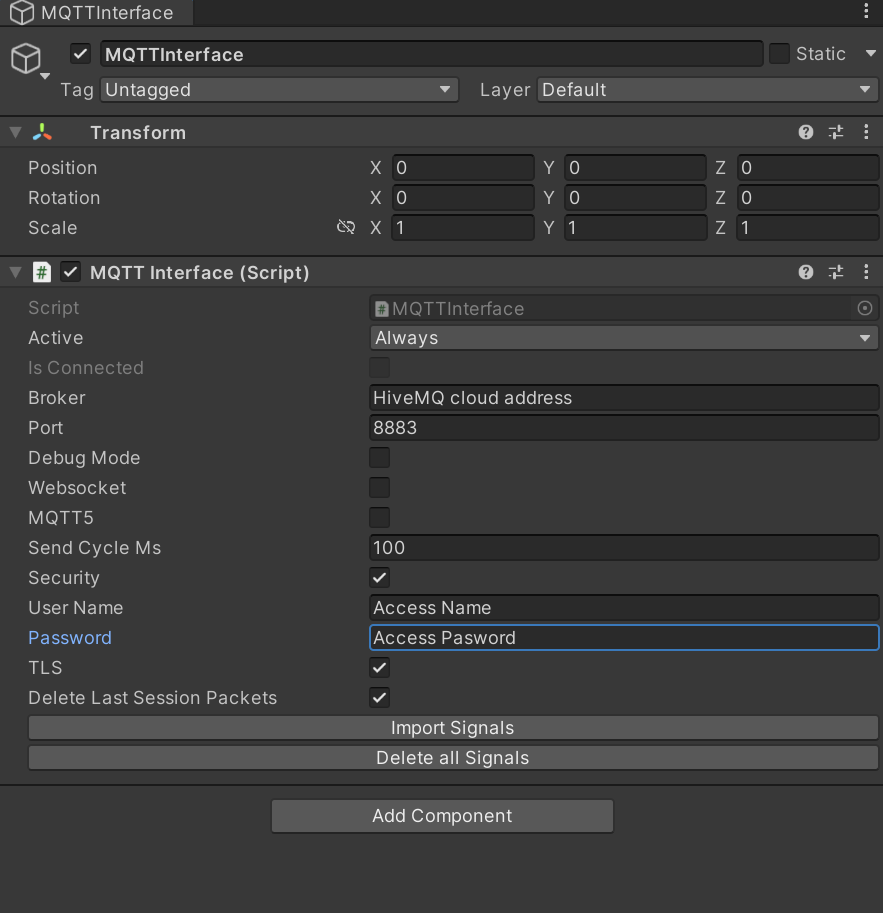

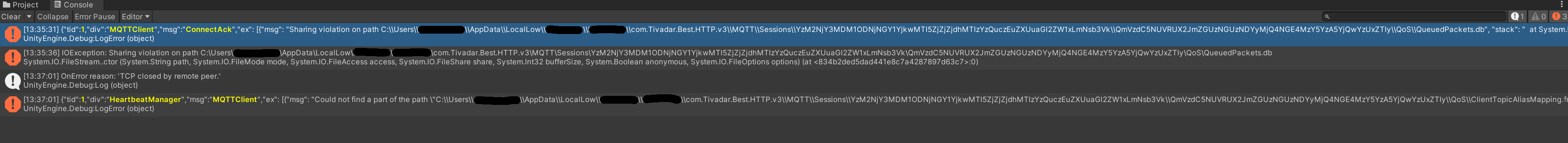

MQTT Interface Error when connecting to HiveMQ Cloud

MQTT Interface Error when connecting to HiveMQ Cloud

I'm having trouble getting Realvirtual MQTT to connect to HiveMQ Cloud. When I test with Python code, everything works perfectly; the connection is established, and I can publish data. However, Realvirtual MQTT reports an error specifically when using HiveMQ Cloud. I've tested both with and without the security option enabled. This issue doesn't occur when using a local MQTT Mosquitto broker.

MQTTInterface

Error

For everybody who needs it - we have a patch for Unity2022. In the next realvirtual 6 release there will be an update also supporting Servers with a large number of MQTT Topics and better failure handling for unsupported datatypes. Also BestMQTT Dependency will be removed.

BESTHTTP compile error

BESTHTTP compile error

Hi,

I am using the realvirtual Pro version

I have a similar issue so I've added a comment to this topic:

https://forum.realvirtual.io/communities/1/topics/687-compile-errors-on-mqtt-interface

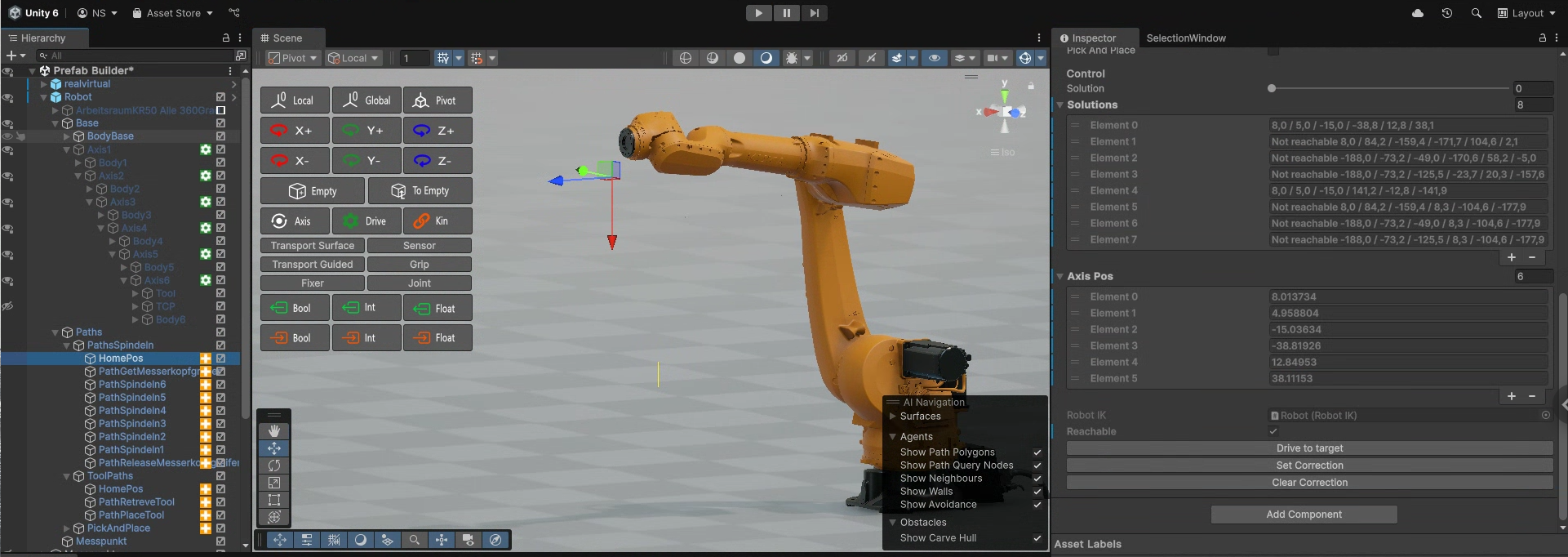

große Abweichungen bei Robot - IK - Targets

große Abweichungen bei Robot - IK - Targets

Hallo,

ich arbeite mit realvirtual Pro und nutze die Inverse Kinematik, um Roboterpfade zu programmieren. Dabei fällt mir auf, dass ich nach jeder Verschiebung eines Targets mehrfach auf „Set Correction“ klicken muss, da sonst eine erhebliche Abweichung entsteht. Besonders problematisch wird dies, wenn die Abweichung so groß ist, dass das Ziel nicht mehr erreichbar ist.

Liegt der Fehler in meiner kinematischen Kette?

Ich verwende einen KUKA-Roboter, den ich in realvirtual nachgebildet habe. Dazu habe ich die Roboter-Vorlage von realvirtual genutzt und die Achspositionen entsprechend angepasst. Die Positionen habe ich in meinem CAD-Programm gemessen. Anschließend habe ich die Körper hinzugefügt. Das beigefügte Bild zeigt die Abweichung ohne Korrekturdaten.

Was könnten Gründe für die großen Abweichungen sein?

Falls dieses Verhalten normal ist: Gibt es einen Weg den "Set Correction"-Vorgang zu Automatisieren, zum Beispiel mit dem selection-manager? (Habe nämlich bereits gut 100 Targets und es werden mehr werden...)

Viele Grüße,

Nico

Siemens Telegram

Siemens Telegram

Hi,

I am using realvirtual.io pro and Unity version 2022.3.12f1. I received a question from a customer asking if I can perform simulations where Siemens telegrams are used.

Is it possible, and which is the best interface to use for this?

They also mentioned that the speed needs to be less than 4ms. This is all new to me, so I would like your opinion.

Telegrams:

Telegram 1, Frequency converters

Telegram 105, Servos

Telegram 83, Pulse encoders

Telegram 750, Additional Torque Data

How to use drive action in behavior subgraphs

How to use drive action in behavior subgraphs

I want to use a Drive action on a behavior subgraph, but I don't know when and how to instantiate the drive. With drive on the blackboard of the subgraph, the drive will not be instantiated.

maingraph

subgraph

NullReferenceException: Object reference not set to an instance of an object

realvirtual.DriveToAction.OnStart () (at Assets/realvirtual/BehaviorGraph/DriveToAction.cs:27)

I have to override Axis in the main graph to create an instance of the drive:

But this is not what I want. I want to use the subgraph for a specific drive, without telling the subgraph all the time which drive. How can I create it?

Customer support service by UserEcho