Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Importing Nodes and performance

Importing Nodes and performance

I just got started with OPCUA. I have a Siemens S7-1500 connected via ethernet cable. I can connect to it and read the nodes, but I can't import nodes via OPCUA Interface. I also did a test with GetAllSubnodes(topnodeid) and it found all 9 nodes it should.

My biggest issue however is using the data. If I use the recommended subscribe method, it is simply too slow (updates around 2 times a second). If I use the direct method I get the update speed, but fps tanks to unbearable with just 1 node.

How can I get better update rates with the delegate/subscribe method? (or any for that matter)

Unityversion: 2020.3.12f1 LTS

Hi, OPCUA is by itself a very slow connection. It has much communication overhead and the S7 OPCUA server is also as far as I know limited to 100ms cycle time. If you need fast update rates you should use S7 TCP, this is much faster. So OPCUA is mainly usefull for HMI stuff but not for fast sensor and axis data.

Hello Thomas,I wish I could use ModbusTCP Client while I'm alive。

Hello Thomas,I wish I could use ModbusTCP Client while I'm alive。

Hello Thomas,I can't connect unity to FX3U until now,I notice FX3U could be ModbusTCP Server,so I want try ModbusTCP client in unity。I wish G4A could have ModbusTCP client function,thank you Thomas。

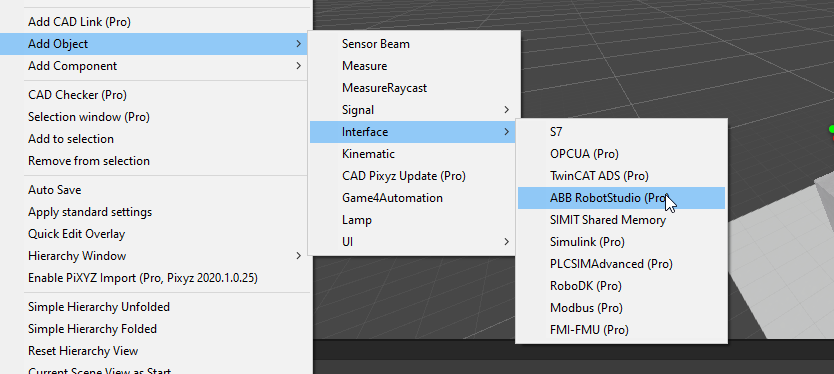

Hello Thomas,I want to connect to RobotStudio。

Hello Thomas,I want to connect to RobotStudio。

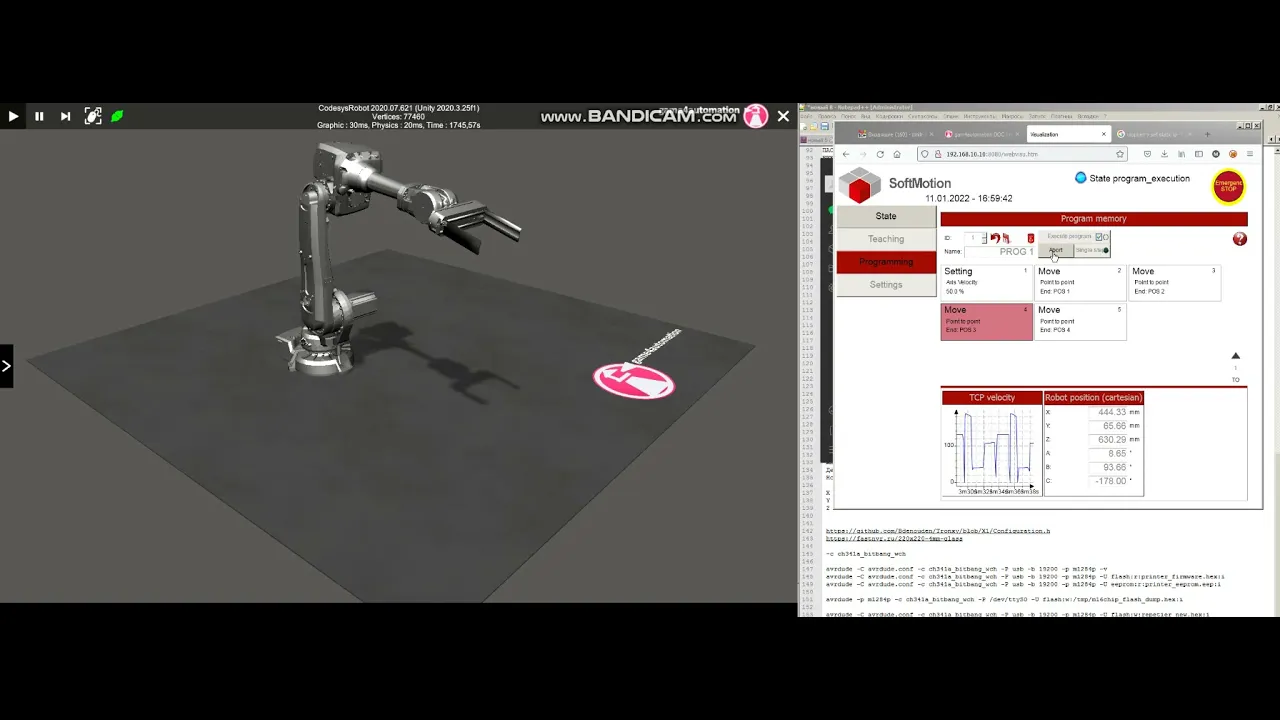

I watched your video(ABB RobotStudio with Unity and Game4Automation)it show you use OPCUA to connect,I want to use OPCUA too,but I don't how to do it,could you make a video show me how to do it?Thanks very much!

This interface is working without Simit it is just using the Simit Interface on ABB Robot Studio side (G4A is acting like Simit)

Runtime UI

Runtime UI

I love this asset, it's awesome, however, I want to show the number range slider in the runtime inspector. I have seen that the Runtime Inspector & Hierarchy has updated and it can show the number range slider in the inspector, so could you update the runtime UI?

S7 - 300 Classic

S7 - 300 Classic

Hallo zusammen,

gibt es eine Möglichkeit ein S7 - 300 Classic Programm (Simatic Manager V5.6 + SP2) mit dem S7 Interface in Unity zu verbinden? Oder gibt es eine andere Alternative?

Das Programm konnte ich bisher nicht auf PLC SIM Advanced in eine Instanz laden.

Sie müssten sich mit dem S7 Interface zu jeder Siemens PLC verbinden können wenn Sie als Hardware vorhanden ist.

CAD object does not exit in QuickToggle.cs Error

CAD object does not exit in QuickToggle.cs Error

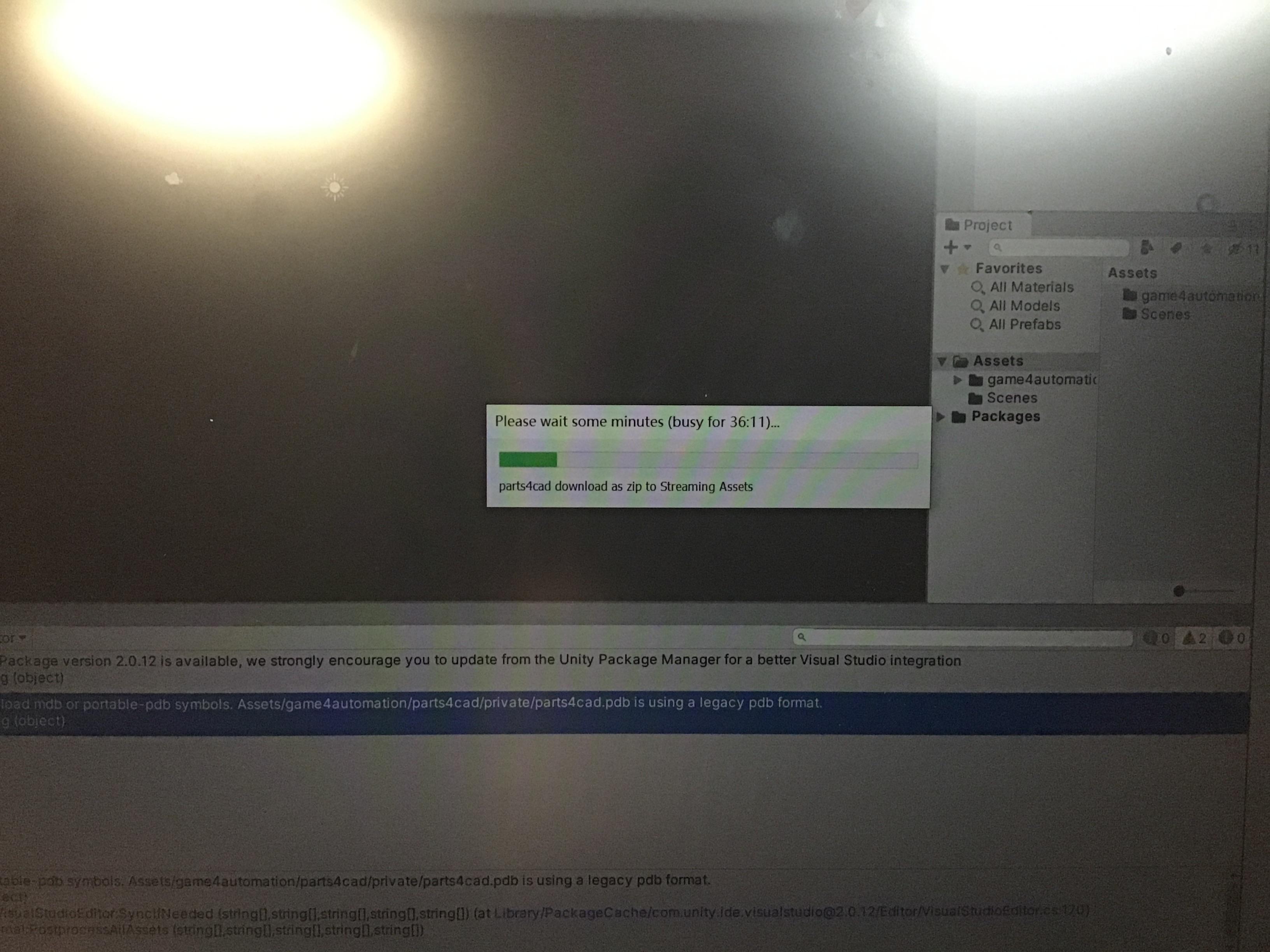

So I just updated to Game for Automation Starter 2020.09 while working on a project and unfortunately, I seem to be getting the following related errors that cannot allow me to proceed at least in Play Mode:

- "Assets\game4automation\private\QuickToggle.cs(418,26): error CS0246: The type or namespace name 'CAD' could not be found (are you missing a using directive or an assembly reference?)"

- "Assets\game4automation\private\QuickToggle.cs(480,36): error CS0103: The name 'CADStatus' does not exist in the current context"

I am using Unity 2020.3.17f1. I've even created a new project and ran the DemoGame4Automation scene but still have the same error. I'm relatively new to g4a so maybe there maybe something I'm missing however as I've already implied, the pretty much everything was working before the update.

We will check why this still happens - we need to look for a more robust solution in setting the correct compile settings while first installing the asset.

KepserverEX 6 and OPCUA Interface of Game4Automation

KepserverEX 6 and OPCUA Interface of Game4Automation

Hi everyone!

Someone with experience connecting KepserverEX6 and OPCUA Interface of Game4Automation, and also writing and reading tags between them.

Regards!

Connection Problem

Connection Problem

game4automation: Object [Siemens S7] TCP : Connection Error: Siemens S7 (game4automation.S7Interface)

UnityEngine.Logger:LogError (string,object)

game4automation.Game4AutomationBehavior:Error (string,object) (at Assets/game4automation/private/Game4AutomationBehavior.cs:496)

game4automation.S7Interface:ConnectS7 () (at Assets/game4automation/private/Interfaces/S7TCPIP/S7Interface.cs:496)

game4automation.S7Interface:CheckConnection () (at Assets/game4automation/private/Interfaces/S7TCPIP/S7Interface.cs:478)

game4automation.S7InterfaceEditor:OnInspectorGUI () (at Assets/game4automation/private/Interfaces/S7TCPIP/Editor/S7InterfaceEditor.cs:31)

UnityEngine.GUIUtility:ProcessEvent (int,intptr,bool&)

How to solv this Problem?

You could youse PLCSIM Advanced or PLCSIM with NetToPLCSim (https://mirror-networking.com/docs/).

Second solution should work but it is not officially supported.

Customer support service by UserEcho