Teilen Sie Ihre Erfahrunge und Wünsche mit uns und anderen Usern!

Robot IK Path (Target 0) Program - Not reachable

Robot IK Path (Target 0) Program - Not reachable

Hello. Realvirtual team.

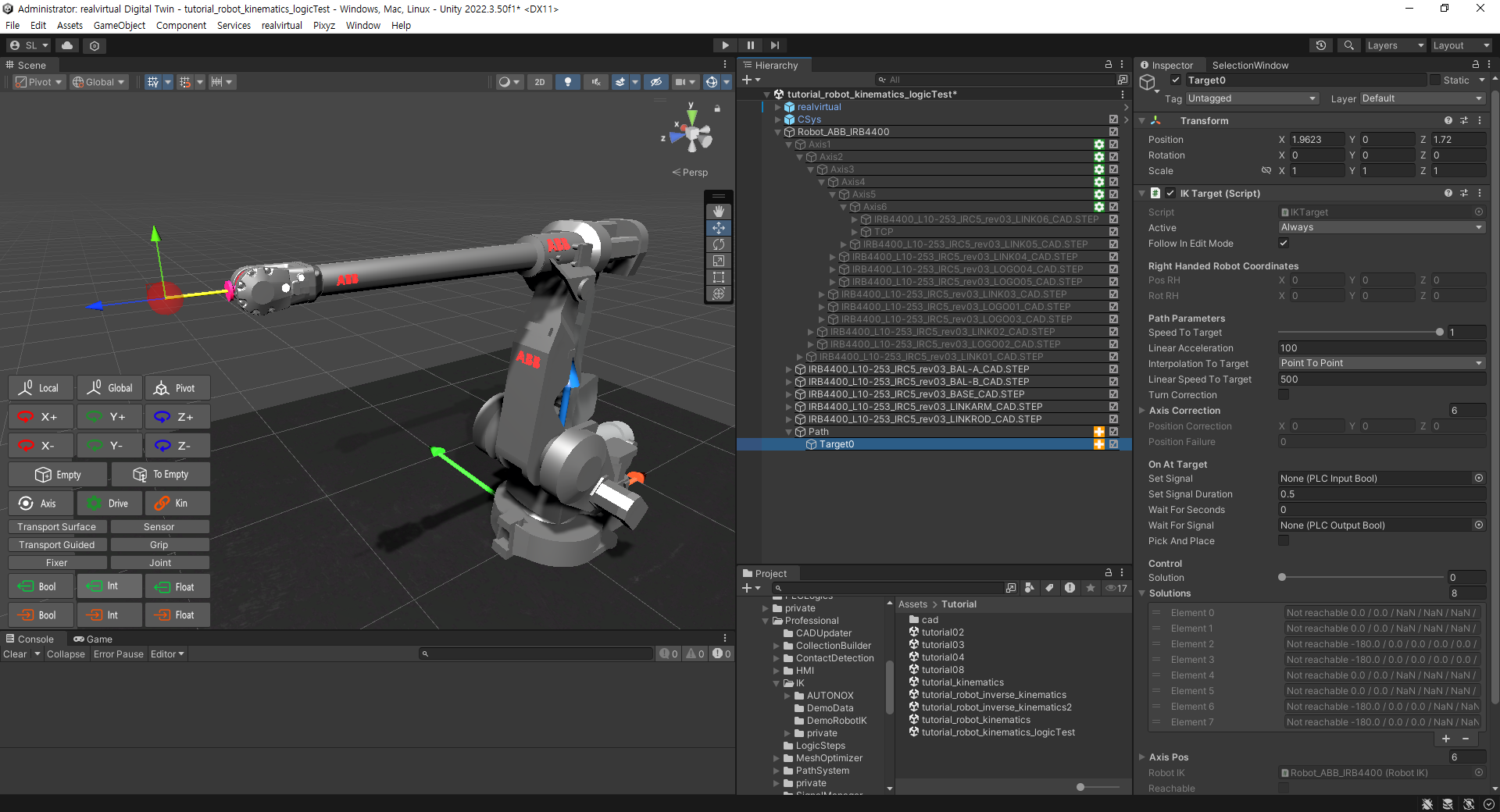

I created a Robot IK Path (Target 0) while learning Robot IK following the realvirtual professional tutorial,

but I have a question because IK cannot reach the Target 0.

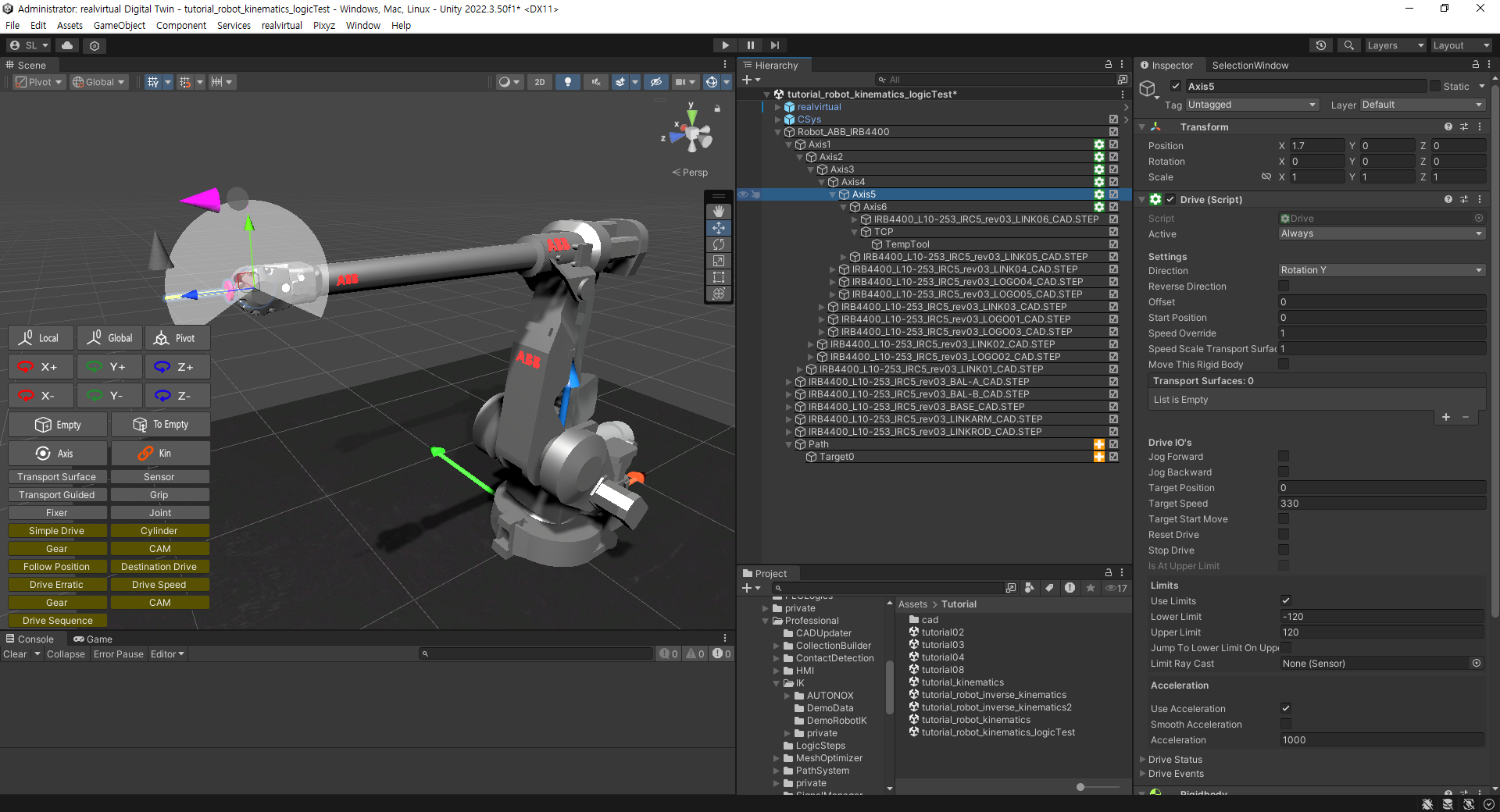

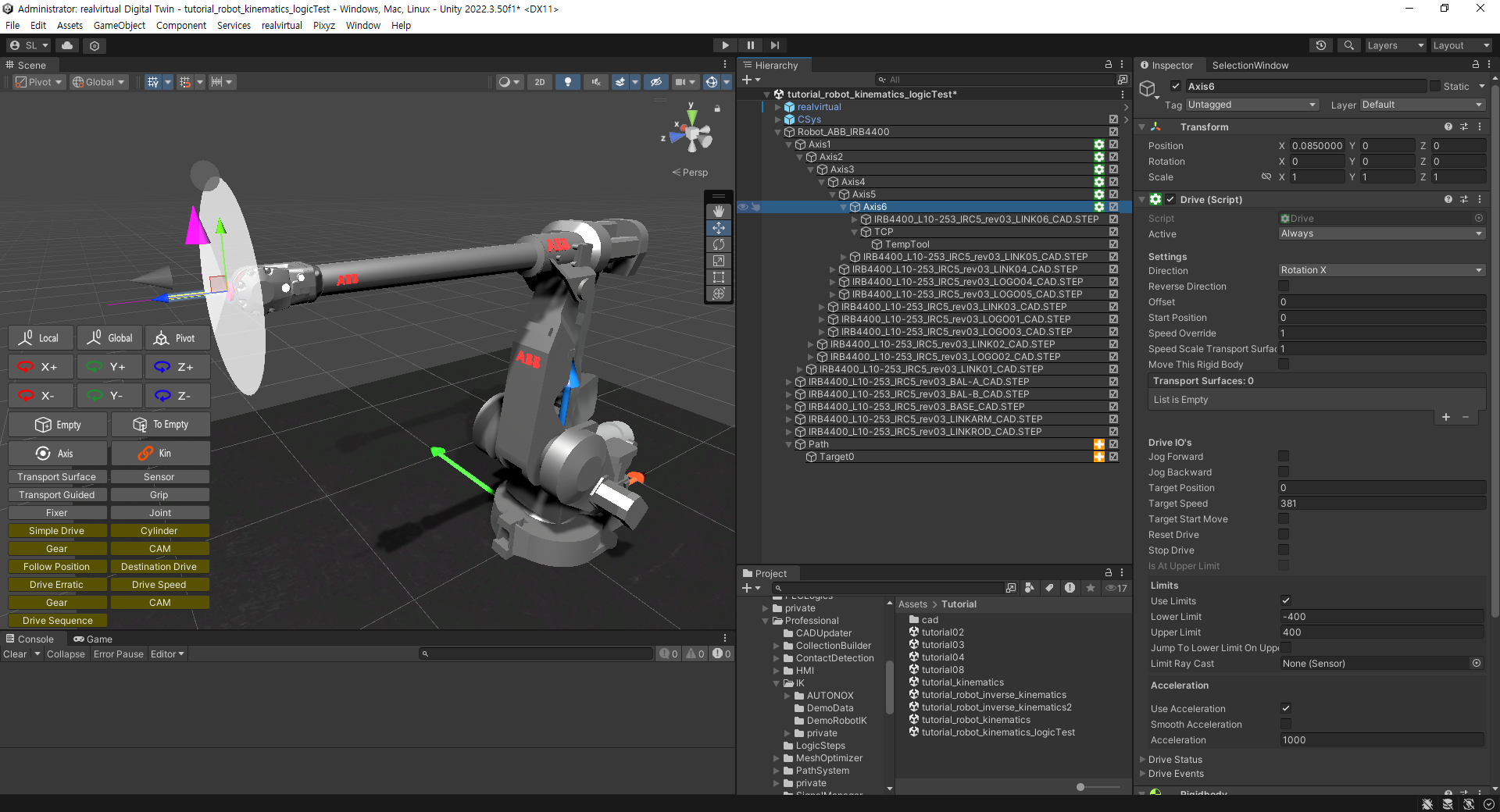

I used the "ABB IRB4400" Robot model and performed the following tasks.

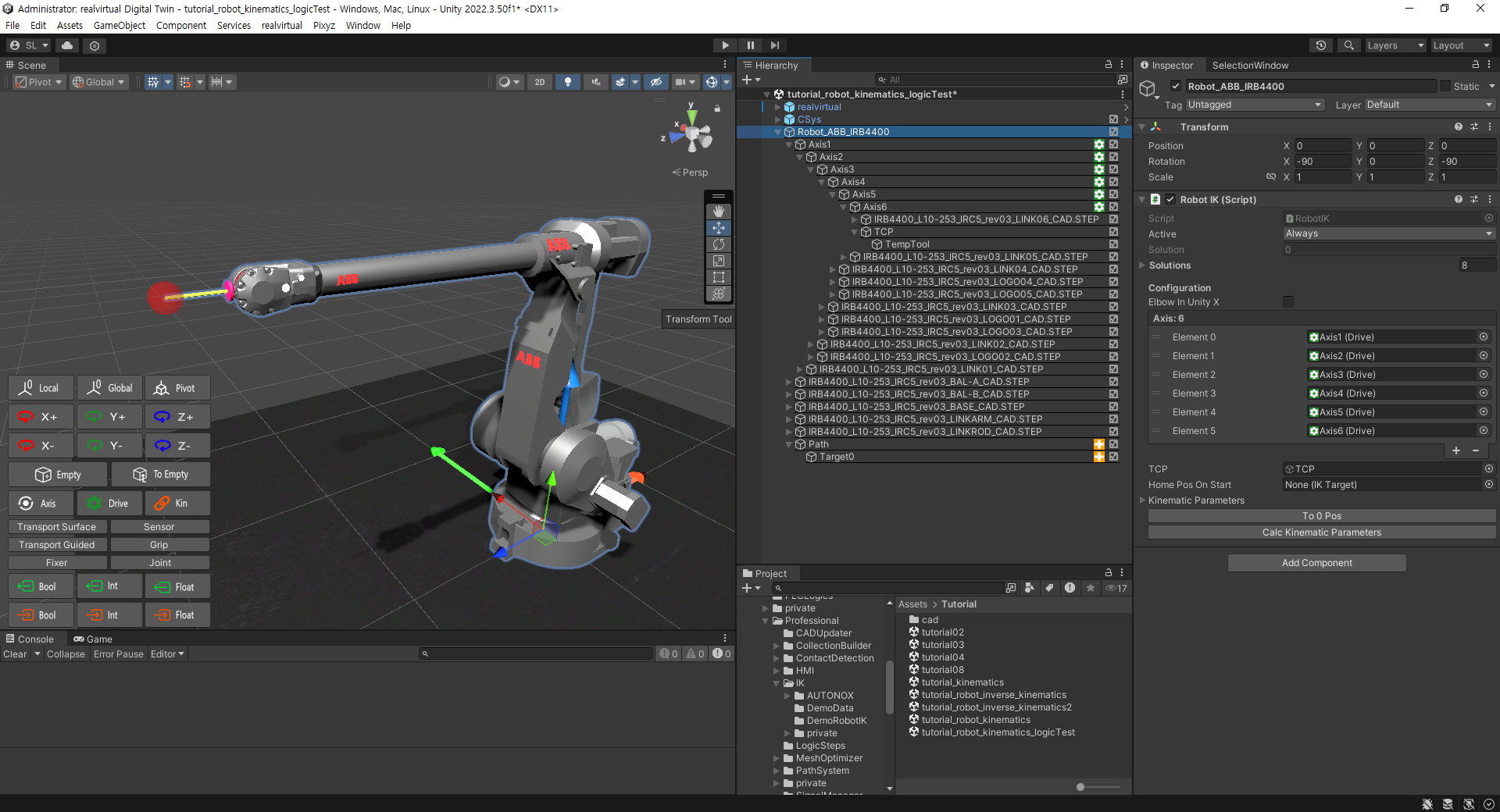

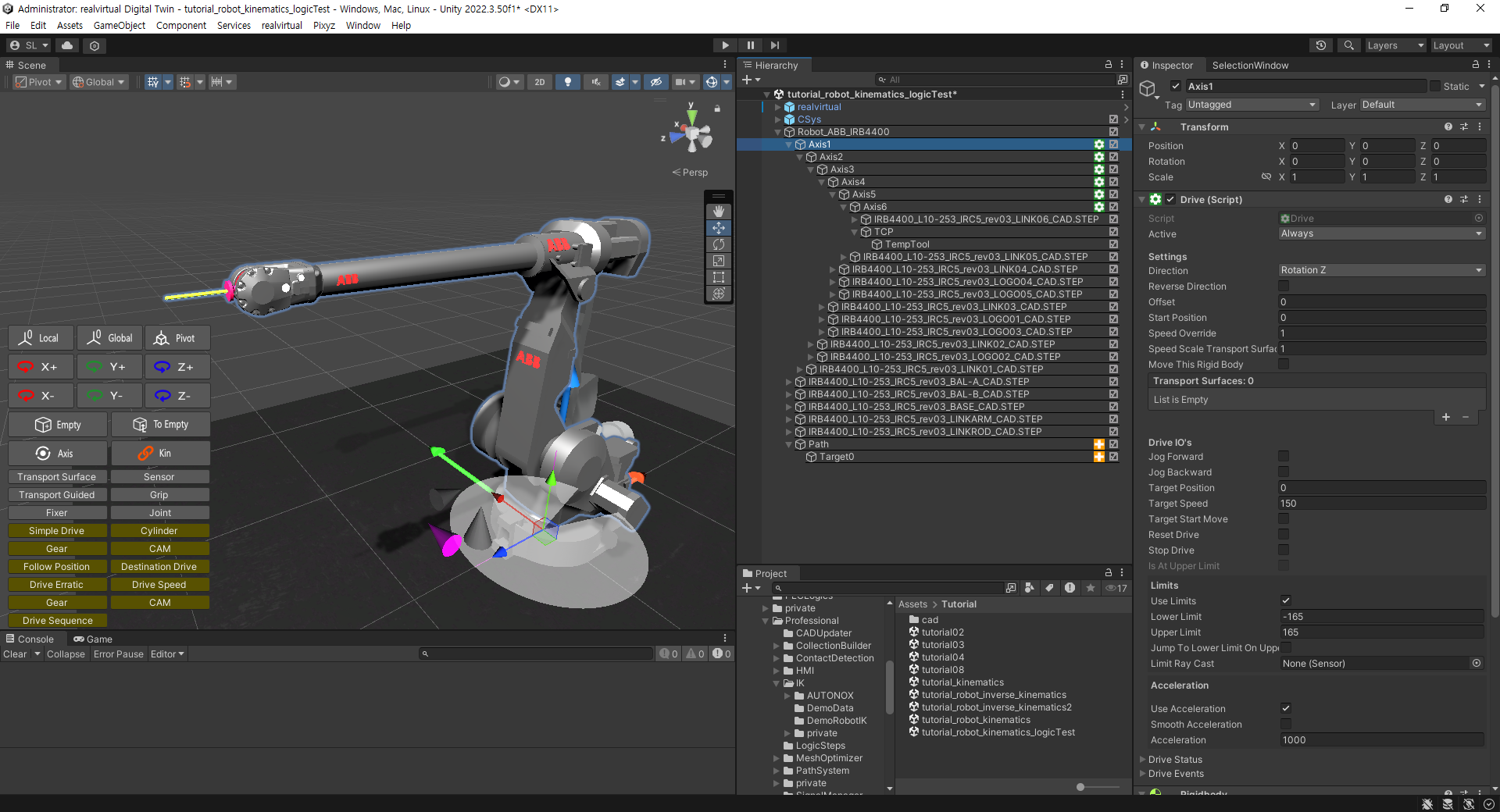

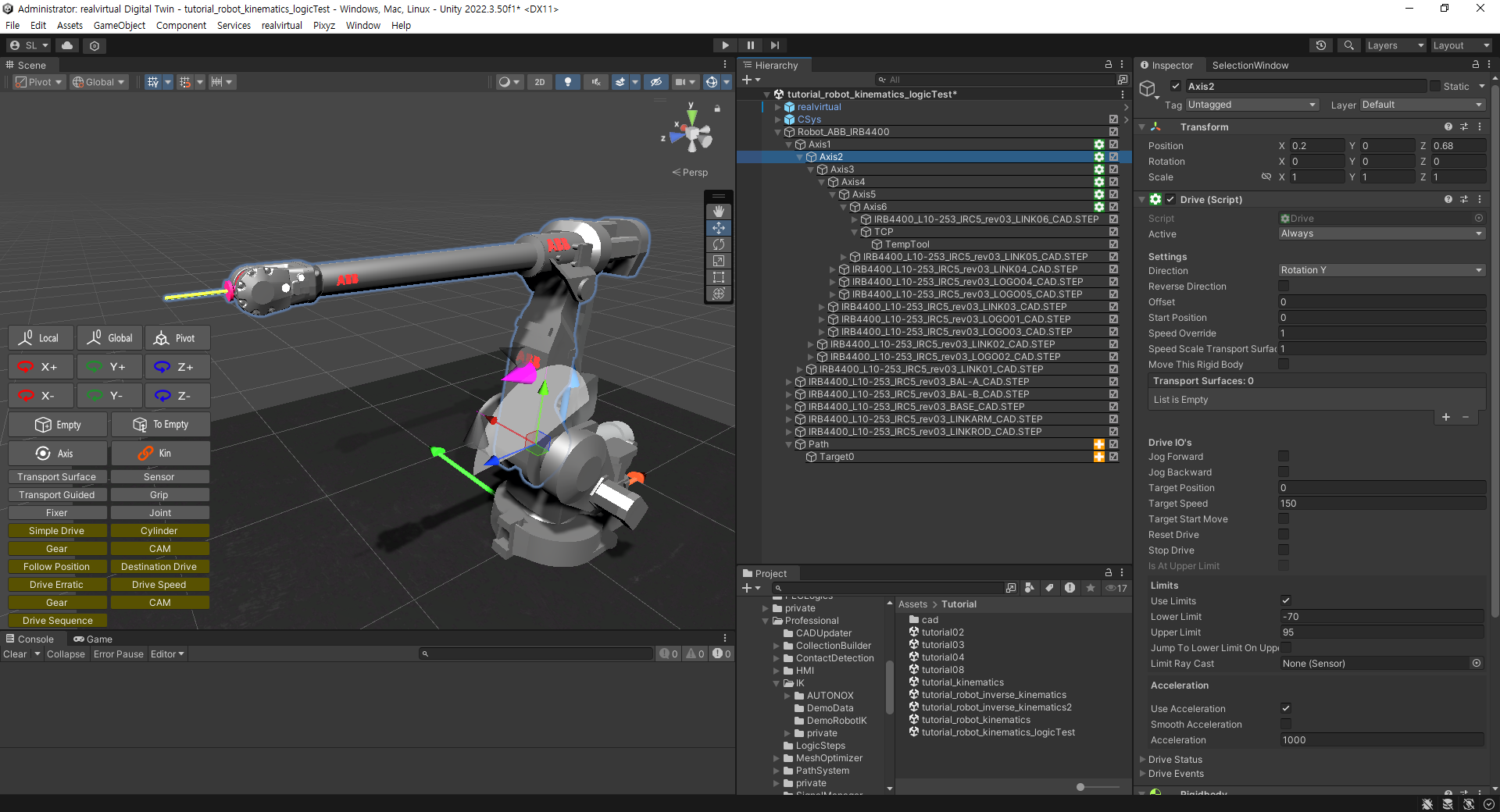

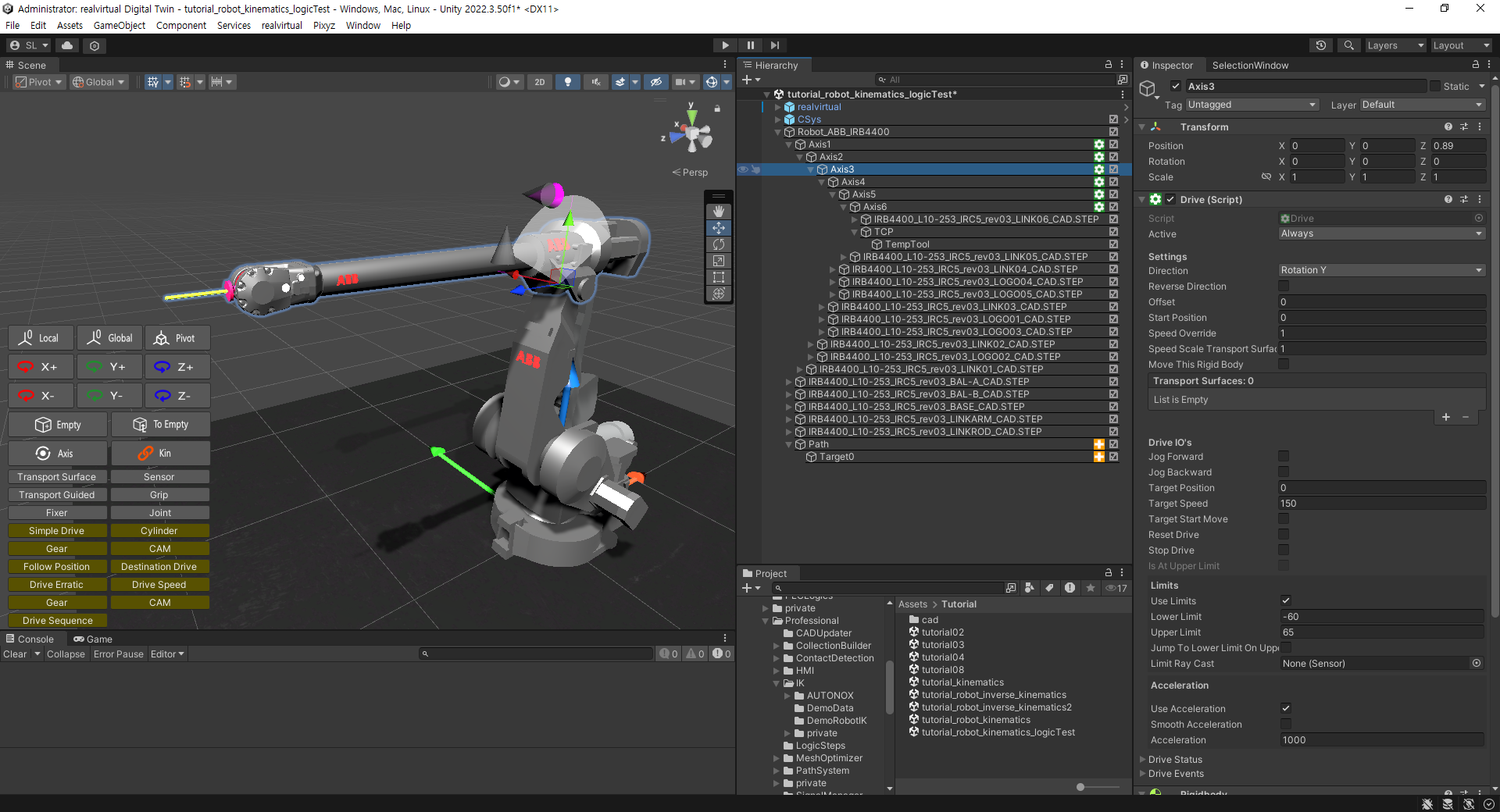

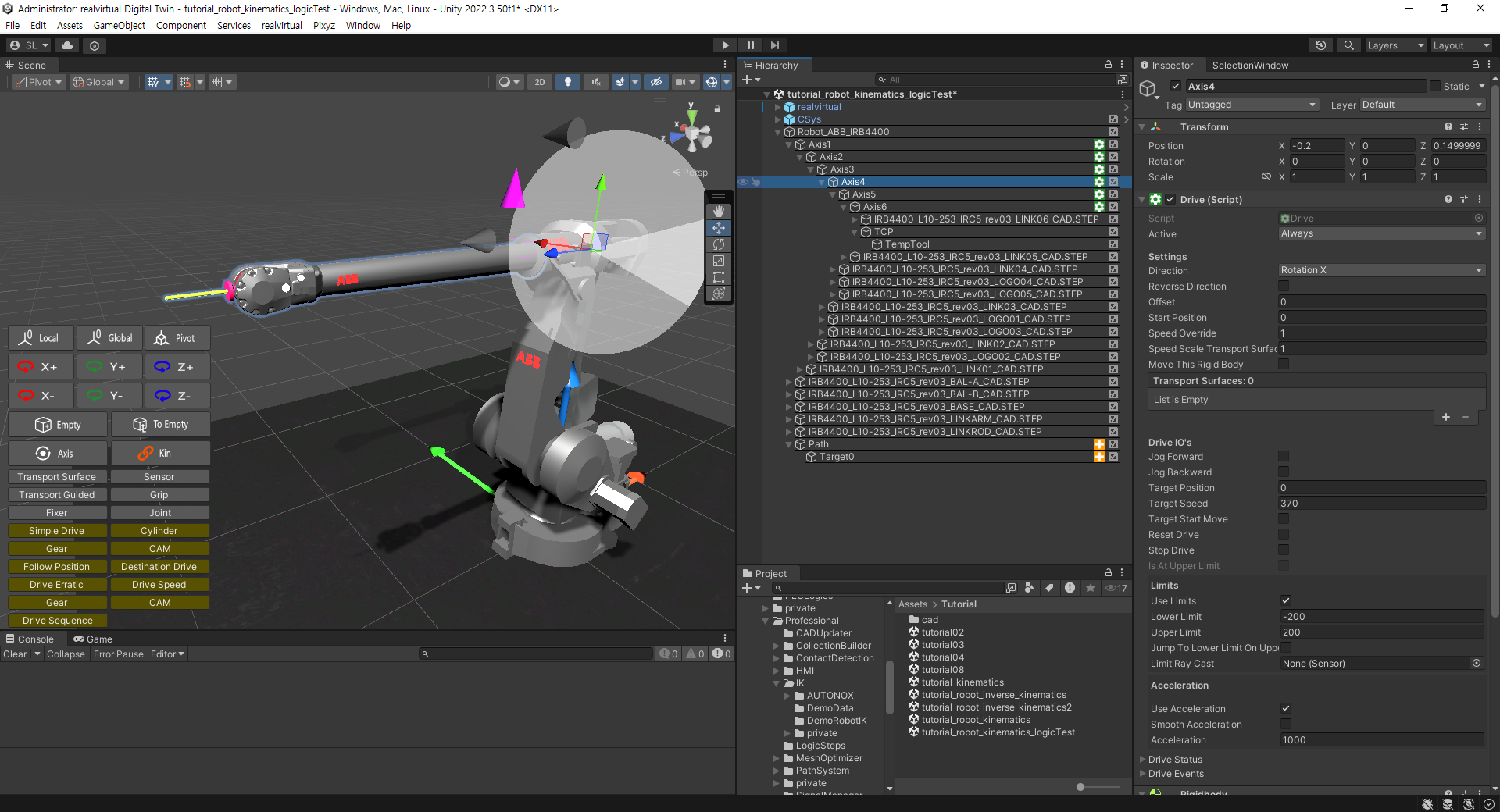

1) Robot 6-axis configuration and Drive settings

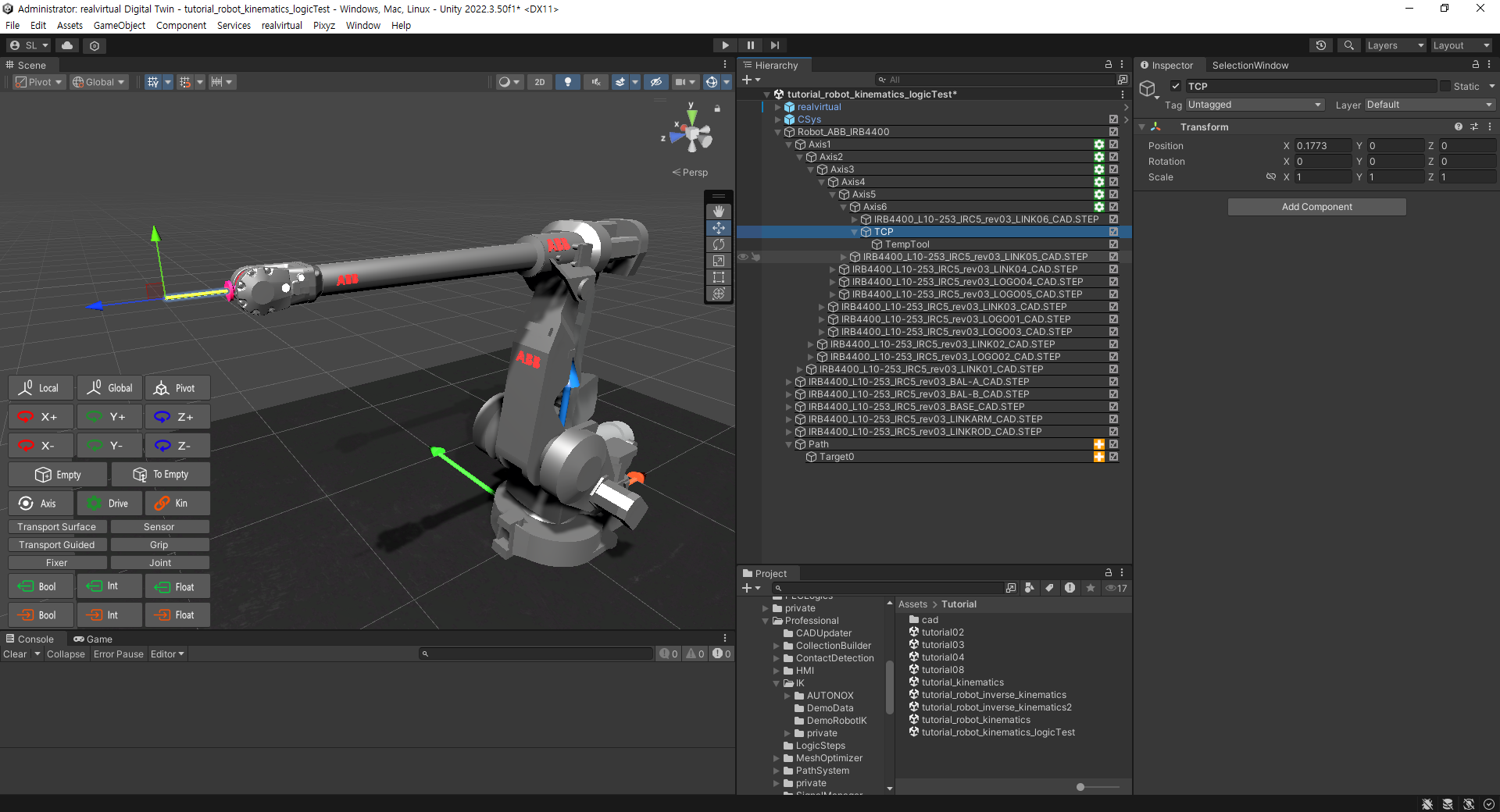

2) Robot TCP configuration

3) Add Robot IK component and then 6-axis and TCP settings

4) Path creation and then IK Path component

→ When I tried Add new Target, it said it cannot be reached. (It is clearly an area that can be reached.)

→ I also tried moving the Target here and there, but the robot does not follow at all.

Can you guide me on where I made a mistake and caused this situation?

Thanks.

Best regards,

Seokhyun Lee

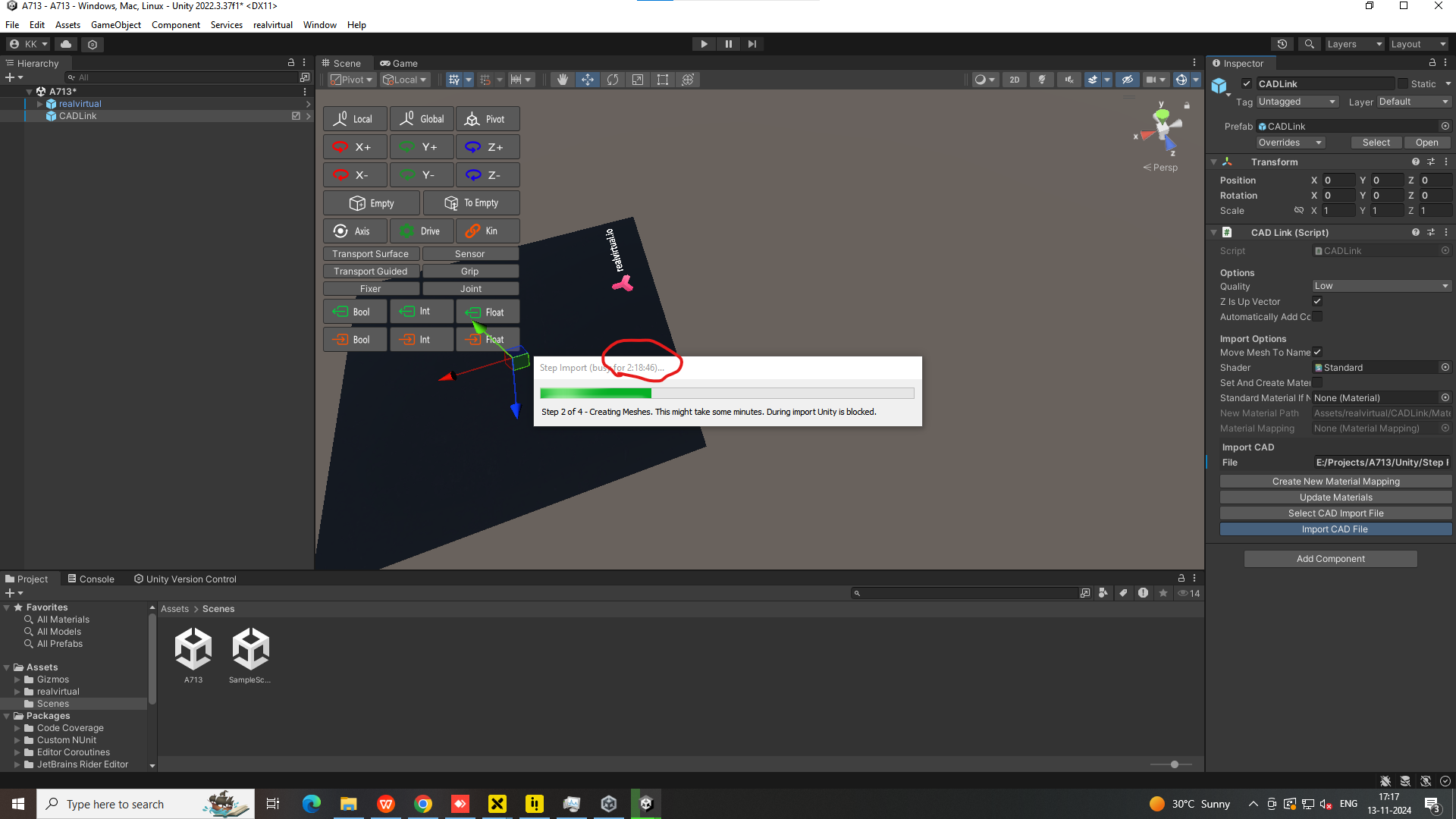

※ Problem Situation (Capture)

※ Robot Setting (Capture)

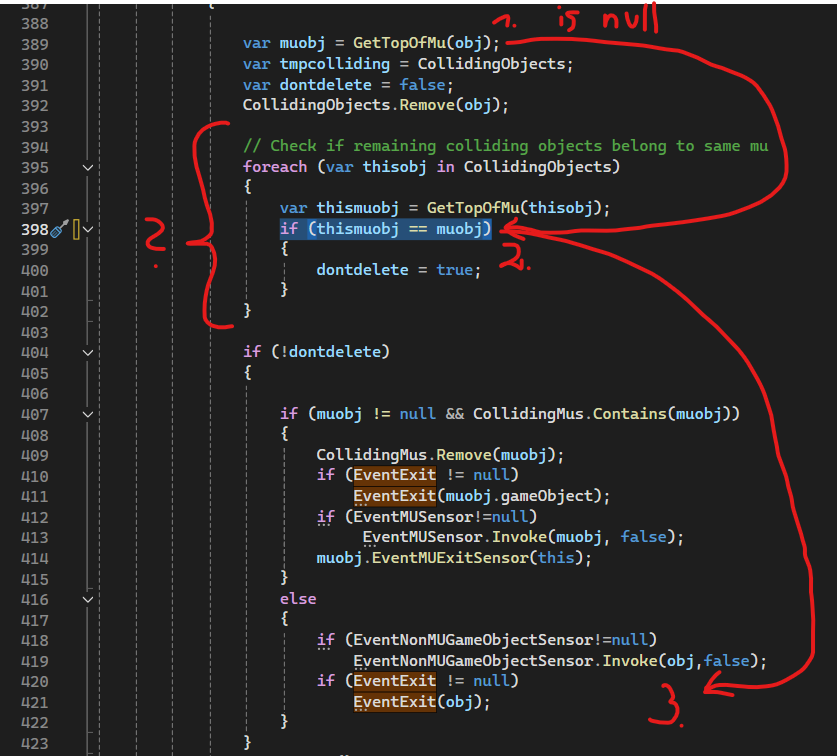

Sensor.cs - Problem in OnTriggerExit

Sensor.cs - Problem in OnTriggerExit

Hello realvirtual team,

on working with the sensor component I encountered an issue in the OnTriggerExit event.

I use the sensor event "EventExit" to trigger logic in my own scripts.

In my application I have a sensor on a MU and this MU stands on a conveyor.

When the MU leaves the conveyor I want to invoke an event in a seperate script.

The problem is that the conveyor is not a MU and therefore "muobj" is null. This is correct.

But because of that the statement "if (thismuobj == muobj)" gets true (both is "null") and the EventExit is not getting invoked.

I am not exactly sure why the foreach statement is necessary.

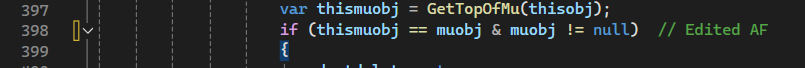

I changed the codeline 398 to this: (so the EventExit is getting invoked)

Please check if this change is a problem in other cases. Maybe you can implement it in the next update.

Thank you very much.

Best regards,

Andreas

Hello,

the "OnExit" event of the sensor is triggered when a MU exits the sensor. If I understand correctly, you’ve attached the sensor as a component of the MU. In that case, it won’t work as intended.

We won’t be changing this in the release because the for-each loops account for the fact that a single MU can consist of multiple colliders, which the sensor may detect.

I recommend the following approach: place the sensor as a standalone GameObject at the end of your conveyor and use it to trigger your script.

Alternatively, you could use Unity's standard OnCollisionExit method on your own component attached to your MU.

Best regards

Christin

Problem with Drive with AGX

Problem with Drive with AGX

Using Realvirtual Release 2022.18 Build 5747

I'm trying to enable a drive while using AGX Physics for collisions.

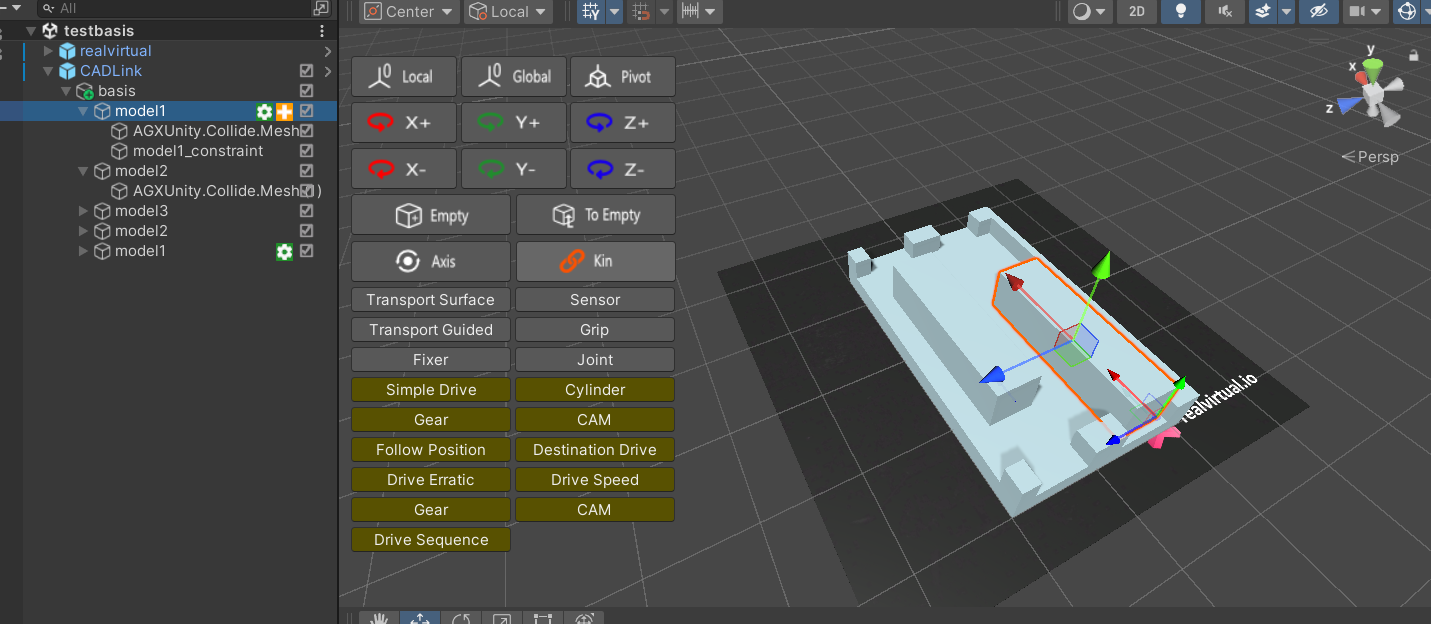

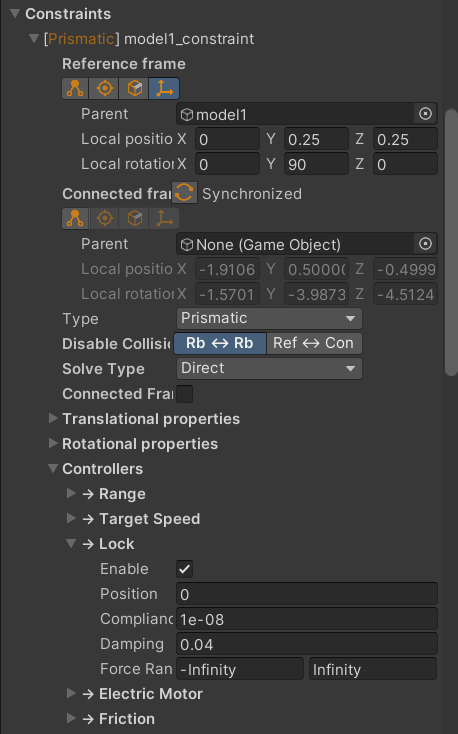

This is the scene I'm using for testing. I'm trying to move the beam on top of the platform and have made colliders in AGX for both. Then I configured a prismatic constraint on the beam through AGX.

Then I followed the instructions of https://doc.realvirtual.io/extensions/agx-physics

I set the lock on of the constraint of the Rigid Body.

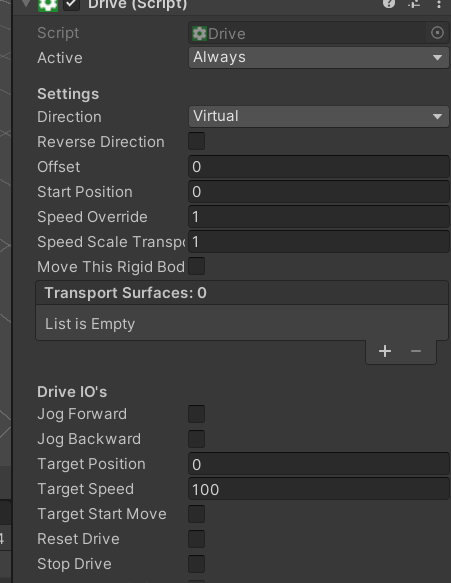

Then I configured the Drive. I put direction on Virtual. Then I added an Erratic Driver.

But when I run the beam doesn't move. Only when I disable the Rigid Body and put the Direction not on virtual the beam moves, but that means disabling AGX Physics. How can I make the beam move while still using AGX?

Hi, how long took it in total? Yes our Step file is not always very fast and it could happen that you need to wait more than 15mins for bigger files.

IK problem

IK problem

1:When using the trigonometric solution, was the DH parameter table used to unify and simplify the relative pose relationships between the joints and links of the robotic arm, serving as an auxiliary tool? Or was it purely a trigonometric solution without the DH parameter table?

2:Can I understand it as using a geometric solution, specifically applying trigonometric methods to calculate and handle the relationships between joints and determine the joint angles?

3:I'm using version 2021.05, and I'd like to achieve real-time IK motion for the robotic arm by directly dragging the TCP in play mode, just like in edit mode, where dragging the TCP instantly moves the entire robotic arm via IK. I don't want to drag the TCP to a position and then click "Drive to Target" to initiate the movement

4:Could you share the source code of the IKCalculator.dll file?

Force drive to move vertical chain

Force drive to move vertical chain

Hello, is it possible to control chain with "Force Drive"? I need to prepare a device which transport load/MUs on shelves arranged in vertical chain. If there is some load on shelves and drive torque is 0, it will move/fall down according

to gravity. On the oder hand, chain is "balanced" if all shelves are empty and will not move even if torque on drive is 0. Is it possible to simulate such device?

Hi,

the current chain only functions with the drive component set to “virtual,” as configured in the sample scene. Using this setup, you should be able to build your device, and Unity physics should operate correctly in this case.

We are using a trigonometric solution which is able to calculate all possible solutions.

Transport surface rotation axle moved from the centre

Transport surface rotation axle moved from the centre

Hello, I've been testing demo scene "MovingTransportSurface". As it is mentioned in the documentation "If the parent drive of the transport surface is rotating, the pivot points (centre of rotation) of both objects must be in the same position for the movement to be transmitted correctly". It is OK if you need to rotate around axle in the centre of transport surface. But I wondering if it is possible to rotate transport surface around axle which is not in the centre of transport surface. It looks like the pivot of the transport surface must be moved, but is it possible to do this?

Hi,

currently it isn't possible to rotate it off-center. We will work on this for the next release.

Regards Christin

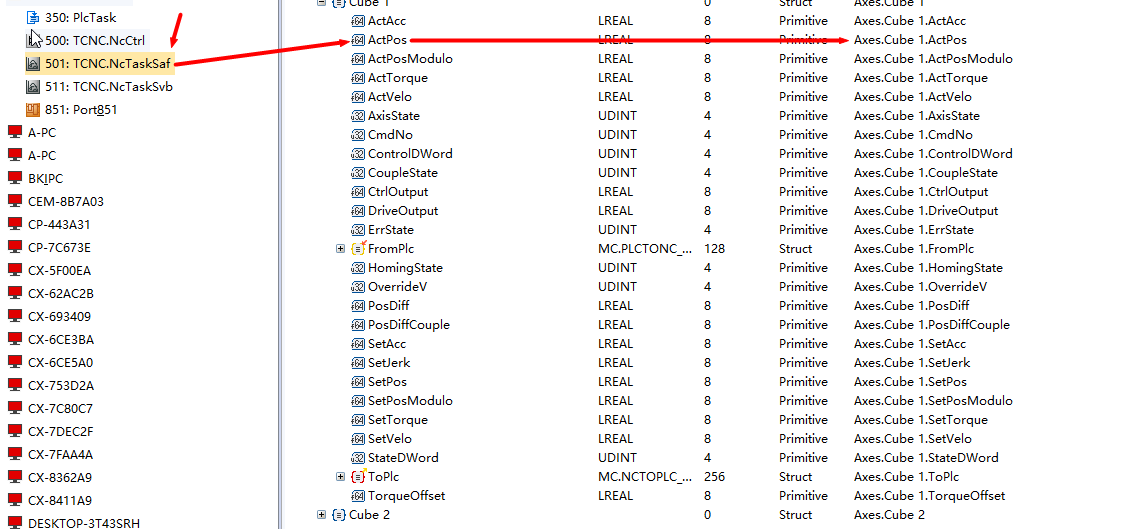

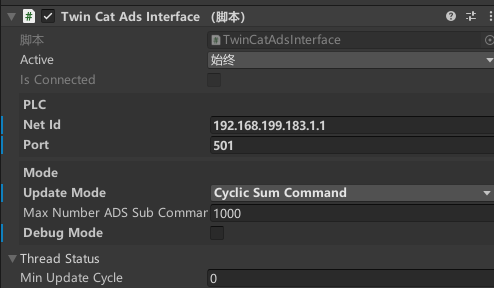

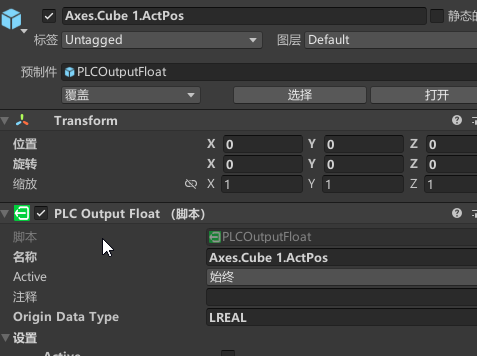

Hello,RealVirtual.IO,How can I get NC Axes information by Twincat ADS(PRO)From ADS Port 501 directly

Hello,RealVirtual.IO,How can I get NC Axes information by Twincat ADS(PRO)From ADS Port 501 directly

Hi,Dear developer,

I want to get TwinCAT3 NC Axes information by TwinCAT ADS From ADS Server Port=501。

It make me quickly get NC Axes symbol From Port 501,do not use any PLC program codeing,it is a very useful Method to get Axis information

But now,I can't connect to Port 501,the port has the only right value which is PLC Project port,such as TC3=851 ,TC2=801

Please give me some ideas about how to get axes information FROM NC PORT 501,thanks

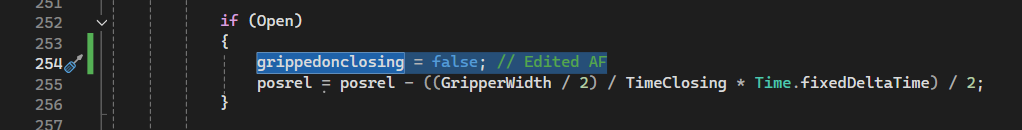

Gripper.cs - Bug with 'grippedonclosing'

Gripper.cs - Bug with 'grippedonclosing'

Hello,

I am trying out the Gripper.cs component and faced a problem with the variable 'grippedonclosing'

After gripping a MU this variable gets set but reset is missing. This leads to the problem that the gripper keeps closing only to the last grippedonclosing position even if no MU is available.

I added this one code line:

Best regards,

Andreas

Hi,

thank you for reporting this issue. We will fix this in the next release.

Best regards

Christin

Customer support service by UserEcho